Robotics has become one of the cornerstones of modern automation, powering industries from electronics and automotive to logistics and healthcare. At the heart of many robotic systems lies a decision between two key motion control technologies: stepper-based designs and servo-driven systems. The choice isn’t just about motors—it’s about how an entire robot arm performs in terms of precision, torque, reliability, and cost over its working life.

A stepping robot arm operates by moving in fixed increments, creating predictable cycles that are easy to control. A servo-controlled arm, on the other hand, relies on feedback to adjust movement in real time, offering smoother motion and consistent torque even at higher speeds. Both have unique strengths and trade-offs, making the comparison highly relevant for engineers, manufacturers, and anyone involved in designing or deploying robotic systems.

Understanding these differences ensures the right balance between performance and investment.

Stepping robot arm vs servo controlled robot arm key differences explained

In this guide we will explain how each system works, where they excel, and the key factors to consider before making a choice.

Why the comparison matters

The choice between a stepping robot arm and a servo-controlled robot arm influences more than just how a machine moves—it impacts efficiency, production flow, and operational costs. In industries where motion control dictates the final outcome, this comparison is critical. Visit here!

- A stepping-driven system relies on incremental steps, creating predictable sequences of movement.

- A servo-based system relies on feedback loops, enabling real-time corrections and dynamic control.

Why it matters:

- Impact on production quality – small positioning errors can add up during thousands of cycles.

- Energy and speed trade-offs – one system consumes more current, the other balances consumption with demand.

- Budget allocation – the upfront cost versus long-term return is not the same for both.

In short, this isn’t about choosing one over the other in general—it’s about aligning the system with the required motion, cycle times, and expected durability.

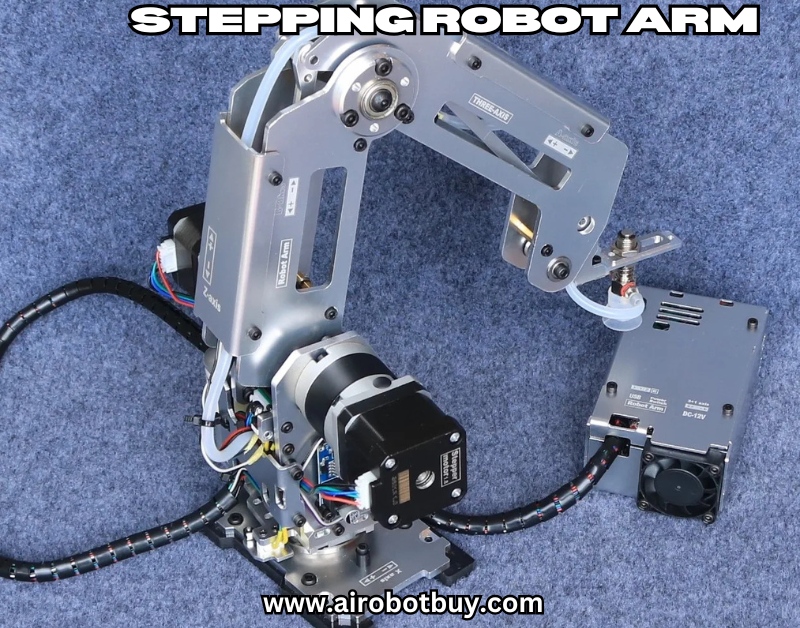

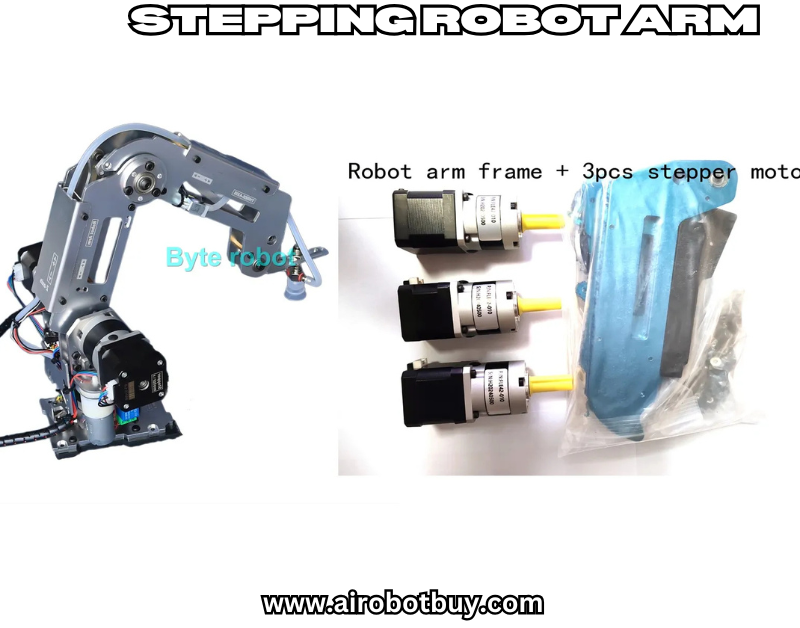

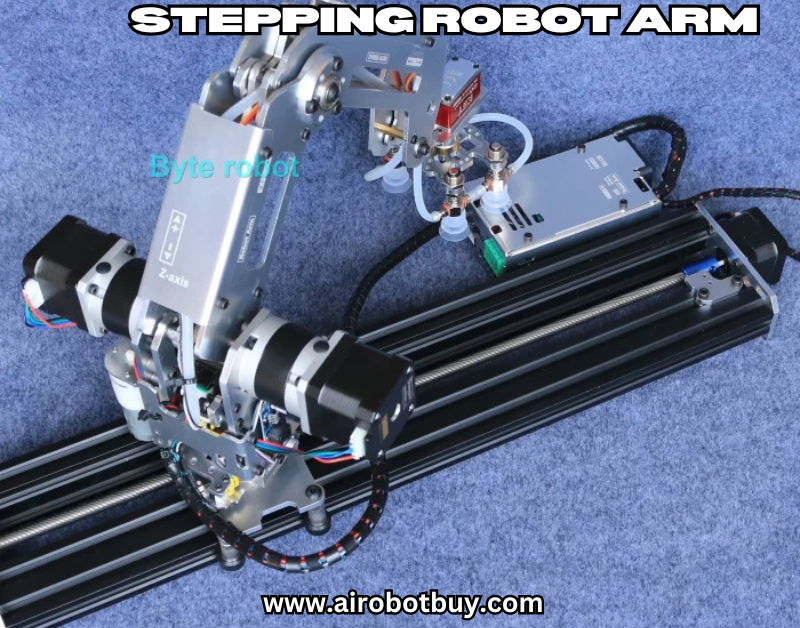

How stepping robot arms work

A stepping robot arm is built on stepper motors, which divide a rotation into discrete steps. Each pulse sent to the motor moves it by a fixed angle. The result is a predictable flow of motion without the need for sensors.

Detailed breakdown:

- Step resolution – A typical motor has 200 steps per revolution, meaning 1.8° per step. With microstepping, smaller increments can be achieved.

- Open-loop design – The system assumes every pulse results in movement. There’s no feedback to confirm, which simplifies the control system.

- Holding torque – Even when idle, the motor locks in place, ensuring the arm doesn’t slip from position.

- Best suited for – tasks like 3D printing, small-scale CNC, and precise laboratory automation.

Advantages in practice:

- Simplicity – no encoders or sensors required.

- Predictability – repeatable cycles, ideal for tasks where reliability is key.

- Lower entry cost – affordable for smaller projects and startups.

How servo-controlled robot arms work

Servo-controlled arms rely on motors paired with feedback devices. Instead of moving in fixed increments, they constantly monitor and adjust their position. The cinematic flow is smoother, with continuous adjustments made during each cycle.

Detailed breakdown:

- Closed-loop feedback – encoders measure actual position, speed, and torque. Data flows back to the controller in real time.

- Dynamic torque delivery – the motor provides only the torque required, improving efficiency.

- High speed – unlike steppers, torque doesn’t fall off at higher RPMs.

- Error correction – if a disturbance occurs, the system recalibrates instantly.

Advantages in practice:

- Precision under load – maintains accuracy even with heavy payloads.

- Energy optimization – draws current only when needed.

- Versatility – capable of handling fast and complex industrial processes.

Direct comparison table

| Feature | Stepping Robot Arm | Servo-Controlled Robot Arm |

|---|---|---|

| Motion style | Discrete steps in sequence | Smooth continuous cycle |

| Control system | Open-loop (no feedback) | Closed-loop with encoder feedback |

| Accuracy | High at low speed, risk of missed steps | Very high, self-corrects in real time |

| Speed range | Limited, torque drops at high speed | High, torque maintained at speed |

| Torque handling | Strong at low RPM, weak at high RPM | Consistent torque across RPM range |

| Complexity | Simple design, easy to program | Complex setup, requires tuning |

| Cost factor | Lower upfront | Higher initial cost |

| Maintenance | Minimal, fewer parts | Requires calibration and upkeep |

| Use cases | 3D printing, light CNC, lab tools | Welding, packaging, automation lines |

Torque and load handling

Torque is where the performance gap becomes obvious. A stepping robot arm can deliver strong torque at low speeds, but once the speed increases, torque decreases sharply. That limits its application in high-speed industrial settings.

Servo arms maintain torque across a broad speed range thanks to closed-loop control. The feedback system ensures the motor delivers only what is needed, whether it’s holding a heavy load still or moving it quickly across a cycle.

Practical insights:

- For light assembly tasks where load is minimal, steppers are efficient.

- For heavy-duty automation requiring strength and speed, servos dominate.

Precision and accuracy in real-world use

Accuracy is not just about movement—it’s about how well a system stays true to its intended path after thousands of cycles.

- Stepping robot arm: Accurate in predictable, low-speed settings, but if overloaded, it can skip steps without warning.

- Servo-controlled arm: Monitors every cycle. Any disturbance is corrected immediately, making it more reliable under unpredictable conditions.

For industries like electronics assembly or automated packaging, the difference in accuracy translates directly into product quality.

Energy efficiency

Energy use is often overlooked but becomes critical in continuous operations.

- Stepping robot arm: Always consumes power, even when holding a fixed position. This constant current draw makes it less efficient over time.

- Servo-controlled arm: Adjusts its current draw according to load and motion sequence. At idle or low demand, it uses far less energy.

This efficiency means servos generally have lower running costs in energy-intensive environments, even if their upfront cost is higher.

Reliability and maintenance

Reliability depends on the design simplicity and moving parts involved.

- Stepping robot arm: With fewer components and no sensors, it’s easy to maintain. Failures are rare, and parts are affordable.

- Servo-controlled arm: Requires encoders, controllers, and sensors. While these add precision, they also increase maintenance needs.

Key points:

- Steppers are rugged and ideal for environments where simplicity is valuable.

- Servos require calibration but deliver unmatched consistency.

pplications where each excels

Different tasks call for different tools.

Stepping robot arm applications:

- 3D printing machines

- Light CNC operations

- Medical and lab automation

- Pick-and-place for small electronics

- Cost-sensitive educational projects

Servo-controlled arm applications:

- Industrial welding

- High-speed packaging

- Robotic assembly lines

- Automated warehouses

- Collaborative robotics research

This separation of use cases shows that neither system is universally better—it’s about matching technology to task requirements.

Cost considerations

Cost can’t be ignored when planning automation.

- Stepping robot arm: Lower purchase price, simpler electronics, reduced setup time. Best for small businesses and projects with limited budgets.

- Servo-controlled arm: Higher upfront investment but delivers savings through energy efficiency, reduced error rates, and higher throughput.

In financial terms:

- Short-term, steppers are more affordable.

- Long-term, servos may reduce total cost of ownership in high-demand environments.

FAQs

Q1. Which is better for beginners?

A stepping system is easier to set up and control, making it beginner-friendly.

Q2. Why do servo systems cost more?

Because they require encoders, sensors, and advanced controllers for feedback-driven accuracy.

Q3. Can both be used in the same facility?

Yes. Many production floors combine both, assigning steppers to predictable tasks and servos to complex jobs.

Q4. Are steppers less modern?

No. They remain vital in precision equipment like 3D printers and lab tools.

Q5. How do I decide between the two?

Consider speed, torque, precision needs, and total budget. Match the system to your real workload, not theoretical specs.

Conclusion

The debate between a stepping robot arm and a servo-controlled robot arm highlights how different approaches to motion control can lead to very different outcomes in automation. Steppers deliver predictable, repeatable movement at a lower cost, making them ideal for tasks where simplicity and budget are the top priorities. Servos, with their feedback-driven precision and ability to maintain torque at high speeds, are better suited for demanding industrial applications where accuracy and efficiency directly impact productivity.

No single option is universally superior—the right choice depends on the specific workload, speed requirements, and long-term cost considerations. For smaller projects or entry-level automation, a stepper-based system can be both effective and practical. For high-volume, precision-driven environments, investing in servo technology often provides greater returns.

The key takeaway is that matching the system to the task ensures reliability and efficiency without overspending. By weighing torque, accuracy, energy use, and maintenance needs, decision-makers can select the best fit for their operation.