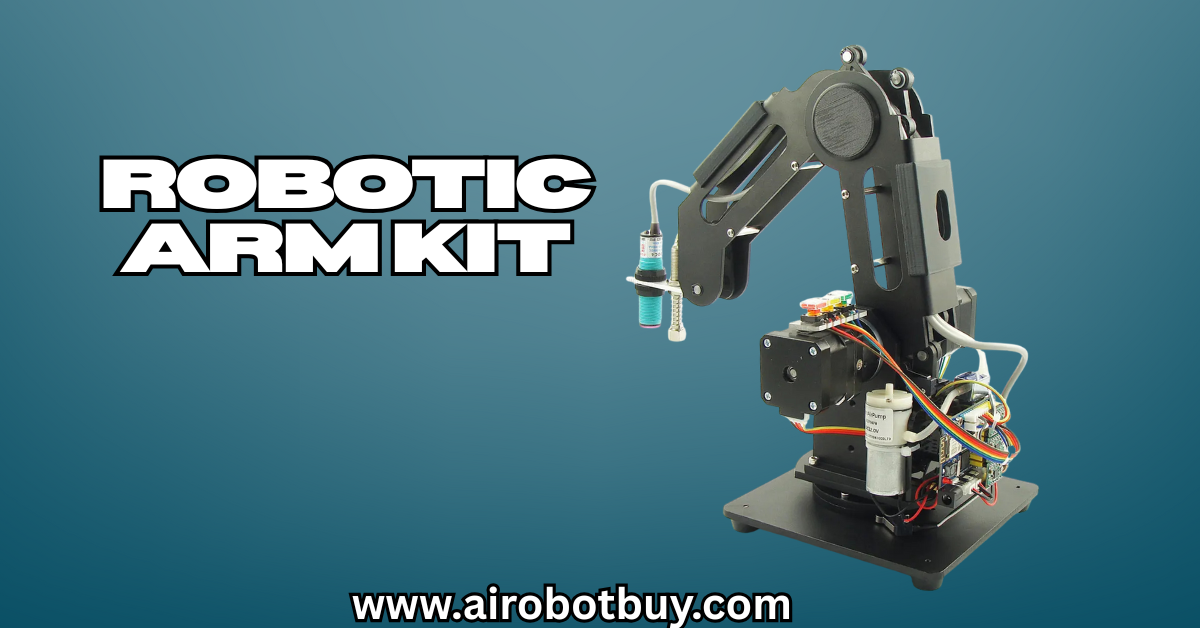

Modern factories are under more pressure than ever to boost efficiency, cut costs, and stay competitive in a fast-changing market. One of the simplest and most cost-effective ways to improve production is through automation—and that’s where stepping robot arm come in. These robotic arms use stepper motors to deliver precise, repeatable movements, making them perfect for high-volume, repetitive tasks like part placement, assembly, packaging, or machine tending. Unlike complex servo-driven systems, stepping robot arms are easier to program, maintain, and scale, making them a smart choice for small manufacturers and large factories alike.

They’re not just a replacement for manual labor—they’re a tool to eliminate inconsistency, reduce downtime, and give your workforce room to focus on higher-value tasks. And with a lower upfront cost compared to other robotic systems, stepping-robot-arm often pay for themselves in a matter of months.

If you’re exploring automation but unsure where to begin, or if you want a flexible, low-maintenance robotic solution, this technology deserves a closer look.

In this guide, we will explain the key benefits of stepping-robot-arm and how they can make a real impact on your factory floor.

Stepping Robot Arm Benefits for Modern Factories

In the age of industrial automation, factories are under pressure to enhance efficiency, reduce costs, and maintain consistent production quality. Stepping robot arms, powered by stepper motors, are emerging as a reliable and economical solution. These robotic arms are designed to perform repetitive tasks with high precision and minimal maintenance. Compared to complex servo-driven systems, stepping-robot-arm are easier to implement and operate, making them ideal for small to medium-sized manufacturing operations as well as scalable for larger setups.

This guide explores the key benefits of stepping-robot-arm in modern factory environments. Each section provides practical explanations without overwhelming technical jargon, using clear language to outline how this technology can drive performance and savings. Visit here!

High Precision and Repeatability

Stepping-robot-arm operate using stepper motors that move in fixed angular steps. This allows for exact movement control without the need for encoders or feedback systems. The precision is built into the motor’s structure, providing consistent positioning accuracy, typically within 0.1 to 0.5 mm, depending on the model.

Benefits:

- Reduces product variation.

- Ensures consistent output in high-volume tasks.

- Ideal for applications requiring accurate part placement, such as electronics assembly or packaging.

The inherent repeatability of stepper motors makes them well-suited for jobs where the same action needs to be performed thousands of times without deviation.

Simplicity in Programming and Setup

Unlike servo-driven systems that may require complex programming and tuning, stepping-robot-arm are generally straightforward to set up. Many systems come with user-friendly interfaces, such as drag-and-drop programming, G-code compatibility, or basic scripting tools.

Benefits:

- Minimal training required for operators.

- Faster deployment into production lines.

- Easier integration with existing manufacturing equipment.

Manufacturers can often get a stepping-robot-arm up and running within days, not weeks, making them practical for dynamic production environments.

Cost-Effective Automation

Cost is a significant factor in automation decisions. Stepping-robot-arm offer a lower initial cost and reduced total cost of ownership over time. They do not require expensive feedback systems, and their motors are generally less expensive to manufacture and maintain than servo systems.

Typical Cost Comparison Table:

| System Type | Initial Cost | Maintenance Cost | Setup Complexity |

|---|---|---|---|

| Stepping Robot Arm | $4,000–$12,000 | Low | Low |

| Servo Robot Arm | $15,000–$50,000 | Medium–High | Medium–High |

Benefits:

- Affordable entry into automation.

- Reduced risk for small-scale manufacturers.

- Faster return on investment (ROI).

Lower Maintenance and High Reliability

Stepping-robot-arm are known for their mechanical simplicity. The lack of brushes, encoders, and complex control electronics reduces the likelihood of failure.

Benefits:

- Fewer breakdowns and production halts.

- Lower spare parts inventory requirements.

- Simplified maintenance procedures.

Routine maintenance typically involves occasional lubrication and inspection of wear components, making them easy to manage even with limited technical staff.

Ideal for Repetitive Tasks

In factory settings where a task must be repeated continuously—such as inserting components, loading machines, or performing the same movement on an assembly line—a stepping-robot-arm excels.

Benefits:

- Eliminates fatigue-related errors from human workers.

- Maintains consistent speed and force application.

- Increases overall production efficiency.

This strength makes them particularly useful in industries like electronics, plastics, light metal assembly, and packaging.

Modular and Scalable Implementation

One of the most practical advantages of stepping-robot-arm is their scalability. You can start with a single unit and expand as needed, without major infrastructure changes.

Benefits:

- Easy to relocate or repurpose.

- Works well in modular production setups.

- Minimal disruption to existing workflow during upgrades.

This flexibility is important in environments where production needs can change based on demand, customer requirements, or new product lines.

Safe Operation in Collaborative Environments

Due to their typically low payload and speed capabilities, stepping robot arm are suitable for environments where humans and machines work side by side. Many models can be equipped with safety sensors or enclosed in light cages for additional protection.

Benefits:

- Improved workplace safety.

- Compliance with safety regulations.

- No need for heavy-duty fencing or full robotic cells.

They’re a good fit for applications in quality control, inspection, and light assembly, where robots can support rather than replace human workers.

Solves Labor Shortages

With skilled labor becoming harder to find, especially for repetitive, low-skill tasks, stepping robot arm help fill the gap. They enable manufacturers to automate monotonous tasks while reallocating workers to roles that require problem-solving or oversight.

Benefits:

- Reduces hiring pressure.

- Supports continuous production during staff shortages.

- Enhances employee satisfaction by reducing repetitive strain tasks.

Energy Efficiency

Stepper motors are efficient at low to medium loads and can be optimized to consume less energy during idle periods or partial duty cycles. While not as efficient as high-end servo systems under variable loads, they perform well in most factory conditions.

Benefits:

- Lower energy costs for repetitive operations.

- Reduced heat generation in smaller workspaces.

- Environmentally friendly option for energy-conscious operations.

Quick ROI and Long-Term Savings

Due to the low initial investment and reduced labor and maintenance costs, stepping robot arm often deliver a return on investment within 6 to 12 months.

Benefits:

- Financially viable for small and mid-sized enterprises.

- Measurable improvements in productivity.

- Sustainable long-term gains through reduced error rates and operational costs.

Frequently Asked Questions (FAQ)

Q1: What tasks are stepping robot arms best suited for?

A1: They are ideal for repetitive, consistent tasks like pick-and-place, light assembly, packaging, machine tending, and testing.

Q2: Can they be integrated with existing PLC or factory systems?

A2: Yes. Many models support standard I/O interfaces and protocols like Modbus, making them easy to connect to factory control systems.

Q3: Are stepping robot arms safe to use near people?

A3: Yes, when operated within their speed and force limits and paired with basic safety precautions, they are considered safe for collaborative environments.

Q4: How long does it take to train staff on using one?

A4: Training typically takes 1–2 days, depending on the system and task complexity.

Q5: What industries benefit the most from stepping robot arms?

A5: Electronics, consumer goods, automotive components, plastics, packaging, and small parts assembly industries are top adopters.

Conclusion

In today’s competitive manufacturing landscape, stepping robot arm offer a reliable, efficient, and scalable solution for automating repetitive tasks without overwhelming complexity or cost. Their core strength lies in precise motion control, low maintenance, and ease of integration—qualities that make them especially valuable for small to mid-sized factories looking to boost output and reduce human error. Whether you’re assembling electronics, packaging consumer goods, or managing a modular production line, these systems can deliver consistent performance and measurable returns.

Unlike traditional robotics that often require significant investment and specialized training, stepping robot arm are simple to deploy and operate. Their flexibility allows manufacturers to adapt quickly to changing production needs, scale up operations gradually, and fill labor gaps without compromising on quality or speed. And with proven use cases across industries, they have earned a strong reputation as a practical automation tool.

For any manufacturer aiming to stay lean, responsive, and cost-efficient, stepping robot arm provide a smart path forward. Their value isn’t just in technology—it’s in the real-world impact they bring to the factory floor.