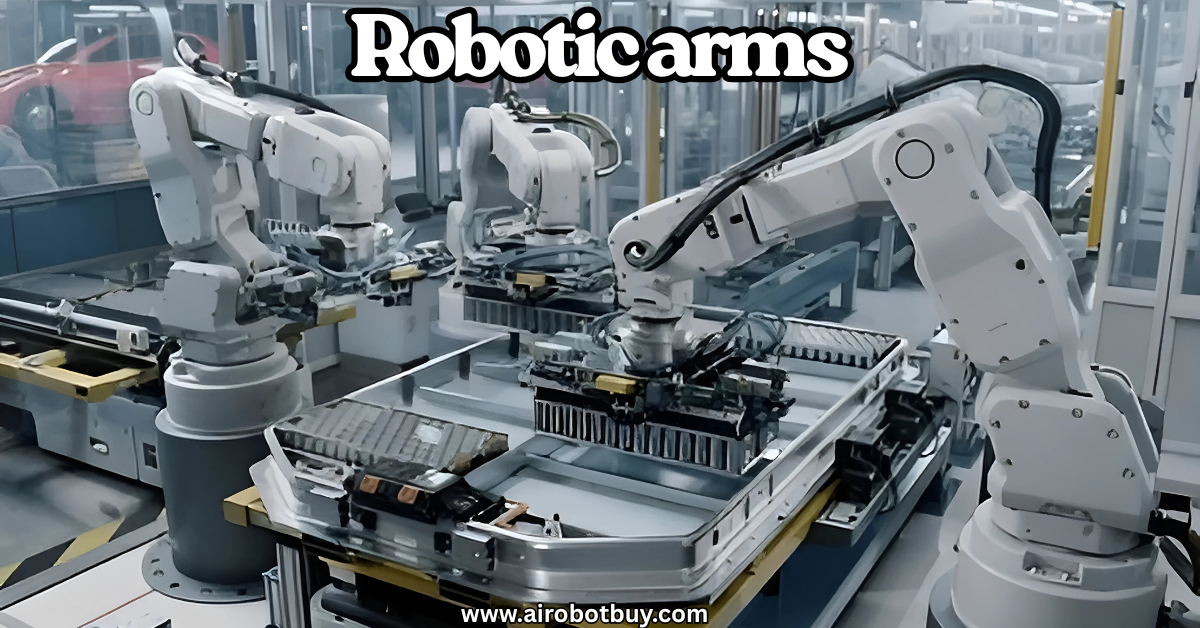

In today’s fast-paced industrial world, robotic arms have become a key driver of efficiency, precision, and innovation. These mechanical arms are designed to mimic the motion of a human limb, but with far greater consistency, strength, and endurance. From automotive factories and electronics assembly lines to hospitals and warehouses, robotic arms are helping companies automate repetitive, high-risk, or high-precision tasks — and they’re doing it 24/7 without breaks or fatigue.

As businesses face growing pressure to reduce costs, improve quality, and increase production speed, robotic-arms are no longer a luxury — they’re a competitive necessity. Thanks to advancements in sensors, programming, and control systems, even small and mid-sized companies are now integrating robotic-arms into their operations.

But how do these machines actually work? What types exist, and where are they being used? Are they safe? Are they worth the investment?

In this guide, we’ll explain what robotic-arms are, how they function in automation, their key components, use cases across industries, benefits, challenges, and everything else you need to know to understand their growing role in modern industry.

Robotic Arms: What They Are and How They Work in Automation

Robotic arms are one of the most recognizable and widely used technologies in industrial automation. Built to replicate the movement of a human arm, these machines are programmable, adaptable, and capable of handling repetitive or complex tasks with high precision. They play a central role in modern manufacturing and industrial operations, increasing efficiency, improving safety, and ensuring consistent output across production lines. This guide explains everything about robotic-arms, including their components, functionality, applications, advantages, and common questions—using a simple, structured approach. Visit here!

What Is a Robotic Arm?

A robotic arm is a type of mechanical arm with joints, links, motors, and sensors that allow it to perform specific tasks like lifting, moving, welding, or assembling parts. It is designed to mimic the structure and motion of a human arm, typically having six degrees of freedom (movement in multiple directions). Robotic-arms are programmable, meaning they can be controlled by software to perform pre-defined or adaptive tasks.

These arms are a subfield of robotics and are used primarily in industrial automation, where they reduce the need for manual labor and ensure high accuracy in operations. They can operate continuously without fatigue, making them ideal for 24/7 environments.

Core Components of a Robotic Arm

Each robotic arm is made up of essential components that work together to perform tasks accurately and efficiently:

- Base: The foundation that supports the entire structure. It keeps the arm anchored in place.

- Joints: Provide movement and flexibility. Each joint adds a degree of freedom.

- Links: Rigid sections that connect the joints, like the bones in a human arm.

- Actuators: Devices (often motors) that power the joints and produce movement.

- End Effector: The tool at the end of the arm (e.g., gripper, welder, suction cup) used to interact with objects.

- Sensors: Provide feedback on position, force, proximity, or vision for more accurate control.

- Controller: The computer or system that interprets commands and controls movement.

- Power Supply: Powers the entire system, typically electric, pneumatic, or hydraulic.

How Robotic Arms Work in Automation

Robotic-arms in automation follow a structured process that ensures efficiency and consistency. Here’s how they work step by step:

- Programming: The arm is programmed with specific instructions. This can be done using coding languages like Python or graphical interfaces for ease of use.

- Movement Planning: The system calculates the most efficient path for the arm to complete its task.

- Execution: Motors and actuators move the joints and links according to the program.

- Feedback Adjustment: Sensors detect position, pressure, or resistance, allowing the system to adjust movements in real-time.

- Repetition: Once trained or programmed, the arm can repeat the process with high consistency.

This cycle allows robotic arms to replace or support human labor in tasks that require speed, precision, or safety.

Applications of Robotic-Arms in Automation

Robotic arms are used across multiple industries for various tasks. Below is a list of common applications:

| Industry | Application Example |

|---|---|

| Automotive | Welding car frames |

| Electronics | Assembling circuit boards |

| Food & Beverage | Packaging and palletizing |

| Pharmaceuticals | Sorting and dispensing medication |

| Logistics | Picking and placing items |

| Aerospace | Riveting and component fitting |

| Healthcare | Assisting in surgeries |

Each of these applications benefits from the robotic arm’s speed, accuracy, and ability to operate continuously.

Types of Robotic Arms

There are several types of robotic arms used in automation. Each type has its own structure and use case:

- Cartesian Robots: Move in straight lines along X, Y, and Z axes. Ideal for pick-and-place tasks.

- SCARA Robots: Used for lateral movements and assembly tasks requiring high speed.

- Articulated Robots: Resemble a human arm with multiple rotary joints. Most versatile in function.

- Delta Robots: Lightweight and fast, often used in packaging and electronics.

- Collaborative Robots (Cobots): Designed to work safely alongside humans without fencing.

Advantages of Robotic-Arms in Automation

Robotic arms provide several operational and financial benefits:

- Increased Productivity: Operate 24/7 without breaks.

- Consistent Quality: Deliver the same result every time, minimizing defects.

- Improved Safety: Take over hazardous tasks, reducing workplace injuries.

- Cost Efficiency: Reduce labor costs in the long term.

- Flexibility: Easily reprogrammed to handle different tasks or products.

Challenges and Limitations

Despite their benefits, robotic arms come with some limitations:

- High Initial Cost: Equipment and integration can be expensive.

- Complex Setup: Requires specialized skills for installation and programming.

- Limited Adaptability: May struggle with tasks that require judgment or irregular object handling.

- Maintenance Needs: Require ongoing calibration, updates, and repairs.

Programming Robotic-Arms

There are different ways to program a robotic arm:

- Teach Pendants: Handheld devices used to manually guide the robot.

- Offline Programming: Software-based programming from a computer.

- Direct Coding: Using languages like Python, C++, or proprietary robot languages (e.g., RAPID for ABB, KRL for KUKA).

The choice depends on complexity, required precision, and available skills.

Safety Considerations

When using robotic arms in automation, safety is critical:

- Emergency Stop Mechanisms: To halt operation instantly.

- Fencing and Barriers: To separate high-speed industrial arms from workers.

- Force Limiting: Cobots often include this to prevent injury.

- Sensors and Vision Systems: To detect human presence and avoid collisions.

Maintenance and Support

Routine maintenance ensures longevity and efficiency:

- Daily Checks: Look for signs of wear, unusual noises, or misalignment.

- Weekly/Monthly Tasks: Calibrate sensors, update software, clean joints.

- Annual Maintenance: Full diagnostic testing and replacement of worn-out components.

Table: Maintenance Checklist

| Task | Frequency | Responsible Team |

| Visual Inspection | Daily | Operators |

| Sensor Calibration | Monthly | Engineers |

| Software Updates | Quarterly | IT/Automation |

| Component Replacement | Yearly | Maintenance Crew |

Q&A Section: Common Questions About Robotic Arms

Q1: How accurate are robotic-arms?

A: High-end industrial arms can have positioning accuracy within 0.01 mm.

Q2: Can robotic-arms be used in small businesses?

A: Yes. Compact and affordable models like cobots are designed for smaller operations.

Q3: What’s the lifespan of a robotic arm?

A: Typically 8–10 years, depending on usage and maintenance.

Q4: Do they require human supervision?

A: While robotic-arms can work autonomously, periodic human monitoring ensures safety and performance.

Q5: Are they customizable?

A: Yes. The end effector, programming, and configuration can be tailored to specific tasks.

Conclusion

Robotic-arms have become an essential part of industrial automation, helping businesses across the globe increase productivity, improve precision, and reduce operational risks. Whether it’s welding in an automotive plant, assembling electronics, packaging food, or assisting in surgeries, these machines are reshaping how work gets done — faster, safer, and with consistent quality.

As technology continues to evolve, robotic arms are becoming more intelligent, more affordable, and easier to integrate, making them accessible not only to large manufacturers but also to small and medium enterprises. While the initial investment and setup can be significant, the long-term gains in efficiency, labor savings, and error reduction often outweigh the costs.

Of course, robotic-arms aren’t perfect. They require thoughtful planning, regular maintenance, and skilled oversight. But when implemented correctly, they offer a powerful solution to modern production challenges.

From their core components to real-world applications and safety protocols, understanding how robotic-arms work is crucial for any business considering automation.