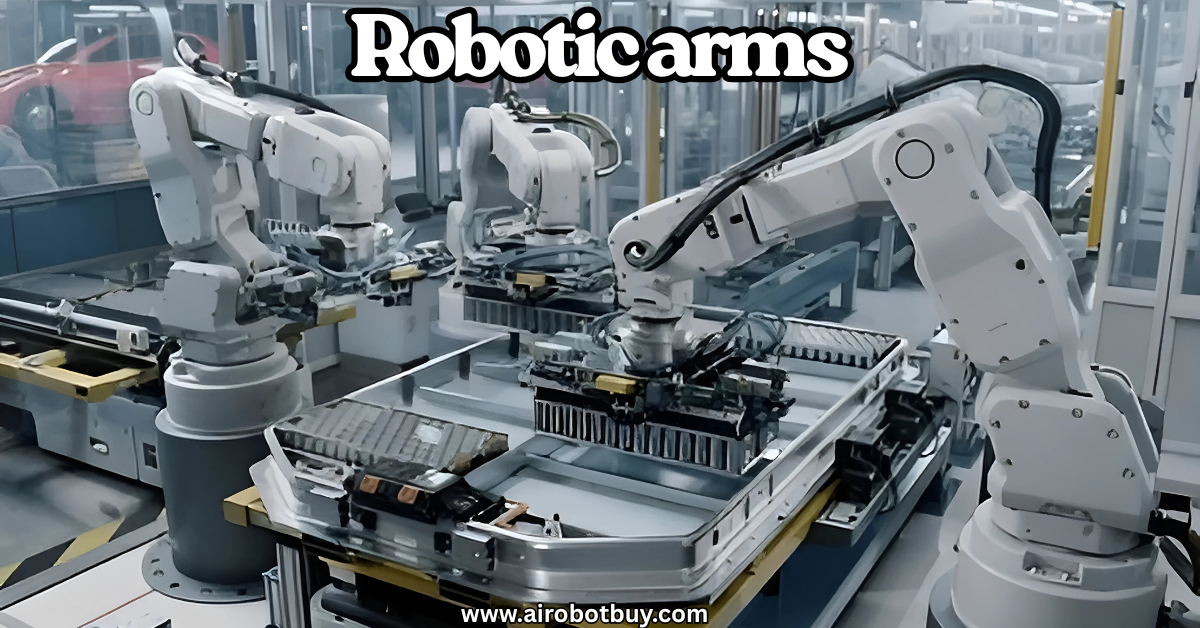

Automation technology is advancing at a pace that few industries can ignore. Among the most influential tools driving this change are robotic arms, which are reshaping how factories, warehouses, and service sectors operate on a daily basis. No longer limited to repetitive tasks in controlled environments, these machines are now smarter, safer, and more adaptable thanks to rapid improvements in sensors, software, and design. Their impact can be seen across sectors such as manufacturing, logistics, healthcare, and even construction, where precision, efficiency, and scalability are essential for growth.

The adoption of collaborative systems, the integration of artificial intelligence, and the focus on sustainability are making robotic-arms a key enabler of next-generation automation. Businesses are not only using them to cut costs but also to create safer workplaces and achieve higher consistency in outputs. As industries move towards flexible production and smart factories, understanding where robotic-arms are headed has become critical for decision-makers.

Robotic Arms Emerging Trends in Automation Technology

In this guide we will explain the latest trends and advancements in robotic arm technology, breaking down their features, applications, and future outlook.

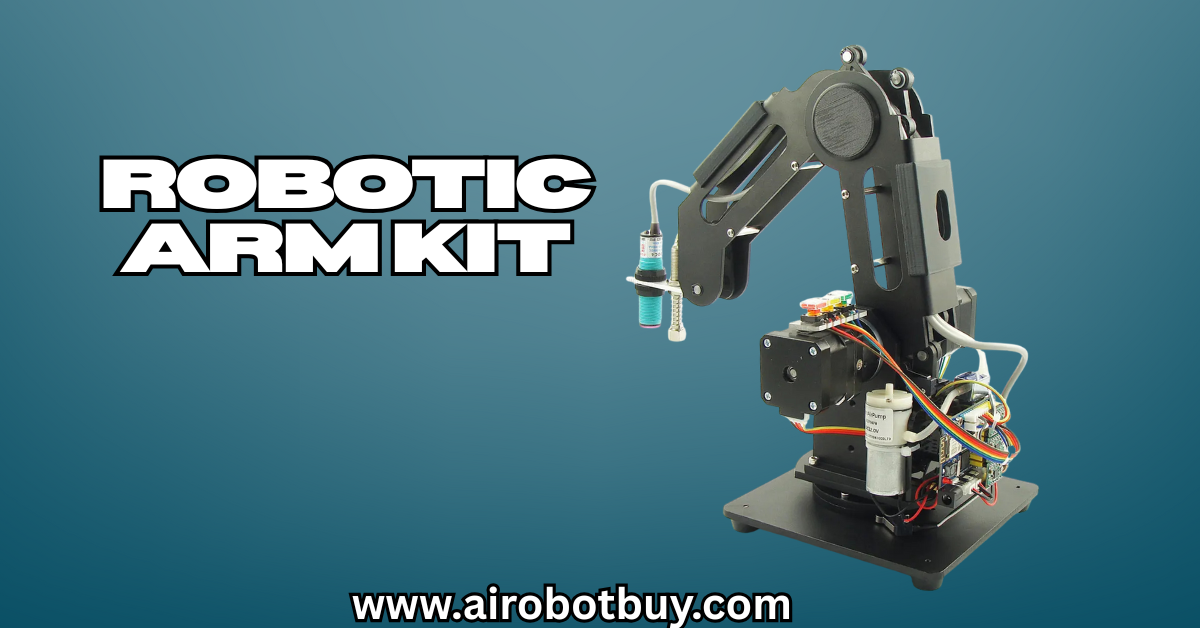

The Rise of Collaborative Robots (Cobots)

Collaborative robots, or cobots, are designed to work alongside human operators, enhancing productivity and safety in shared workspaces. Unlike traditional industrial robots that operate in isolation, cobots are equipped with advanced sensors and safety features, allowing them to interact seamlessly with humans. Visit here!

Key Features:

- Safety Sensors: Cobots are equipped with force and torque sensors that enable them to detect human presence and adjust their movements accordingly, ensuring a safe working environment.

- Ease of Programming: Many cobots offer user-friendly interfaces, allowing operators to program them without extensive coding knowledge.

- Flexibility: Cobots can be easily reprogrammed and redeployed across different tasks, making them versatile assets in dynamic production settings.

Applications:

- Assembly Lines: Cobots assist in tasks such as screwing, welding, and component placement, working alongside human workers to improve efficiency.

- Packaging: In packaging operations, cobots handle repetitive tasks like sorting and packing, reducing human labor and increasing throughput.

- Quality Inspection: Cobots equipped with vision systems can perform detailed inspections, identifying defects and ensuring product quality.

Integration of Artificial Intelligence and Machine Learning

The integration of artificial intelligence (AI) and machine learning (ML) into robotic arms is revolutionizing their capabilities, enabling them to perform complex tasks with greater precision and adaptability.

Enhancements Through AI and ML:

- Predictive Maintenance: AI algorithms analyze data from robotic systems to predict potential failures, allowing for proactive maintenance and reducing downtime.

- Adaptive Learning: Robotic-arms can learn from their environment and experiences, adapting their movements and actions to improve performance over time.

- Vision Systems: AI-powered vision systems enable robotic-arms to identify objects, navigate environments, and perform tasks that require fine motor skills.

Impact on Industries:

- Manufacturing: AI-integrated robotic-arms enhance production lines by performing tasks with high precision and speed, reducing errors and increasing output.

- Healthcare: In medical applications, robotic-arms assist in surgeries and rehabilitation, providing support with delicate procedures and patient care.

- Logistics: AI-driven robotic-arms optimize warehouse operations by automating sorting, packing, and inventory management.

Advanced Sensing and Dexterity

Advancements in sensor technology are enhancing the dexterity and sensitivity of robotic-arms, enabling them to perform intricate tasks with greater accuracy.

Technological Developments:

- Force/Torque Sensors: These sensors allow robotic-arms to apply the right amount of force, preventing damage to delicate components and ensuring precision.

- Tactile Sensors: Tactile sensors provide feedback on texture and pressure, enabling robotic-arms to handle objects with varying characteristics.

- Vision Systems: High-resolution cameras and imaging systems allow robotic-arms to identify and interact with objects in their environment.

Applications:

- Electronics Assembly: Robotic-arms with advanced sensing capabilities can assemble small electronic components, ensuring accurate placement and soldering.

- Food Processing: In food industries, robotic-arms handle delicate items like fruits and pastries, maintaining quality and hygiene standards.

- Medical Devices: Robotic arms assist in the assembly of medical devices, where precision and cleanliness are paramount.

Mobile Manipulators: The Next Frontier

Mobile manipulators combine the mobility of autonomous mobile robots (AMRs) with the dexterity of robotic-arms, creating versatile systems capable of performing tasks in dynamic environments.

Key Features:

- Autonomous Navigation: Mobile manipulators can navigate through complex environments using sensors and AI algorithms, allowing them to perform tasks without human intervention.

- Manipulation Capabilities: Equipped with robotic arms, these systems can handle objects, perform assembly tasks, and interact with their environment.

- Adaptability: Mobile manipulators can be deployed in various settings, including warehouses, hospitals, and construction sites, adapting to different tasks and conditions.

Applications:

- Warehouse Automation: Mobile manipulators transport goods, sort items, and assist in inventory management, improving efficiency in logistics operations.

- Healthcare: In medical facilities, mobile manipulators deliver supplies, assist in surgeries, and support patient care activities.

- Construction: These systems perform tasks such as bricklaying, welding, and material handling, contributing to automation in construction processes.

Sustainability and Energy Efficiency

As industries strive for sustainability, robotic arms are being designed with energy efficiency in mind, reducing operational costs and environmental impact.

Energy-Saving Technologies:

- Regenerative Braking Systems: These systems capture energy during deceleration and feed it back into the power supply, reducing energy consumption.

- Lightweight Materials: Using materials like carbon fiber and aluminum reduces the weight of robotic-arms, leading to lower energy requirements for movement.

- Efficient Motors and Drives: Advanced motors and drive systems optimize energy use, enhancing the overall efficiency of robotic-arms.

Environmental Impact:

- Reduced Carbon Footprint: Energy-efficient robotic-arms contribute to lower greenhouse gas emissions, supporting sustainability goals.

- Waste Reduction: Optimized operations lead to less material waste, promoting resource conservation.

- Longer Lifespan: Energy-efficient designs often result in less wear and tear, extending the operational life of robotic arms.

The Future Outlook

The future of robotic arm technology is poised for continued innovation, with advancements in AI, materials science, and automation driving new capabilities and applications.

Emerging Trends:

- Integration with IoT: Robotic-arms will increasingly connect with Internet of Things (IoT) devices, enabling real-time data exchange and enhanced coordination in smart factories.

- Human-Robot Collaboration: The development of more intuitive interfaces and safety features will facilitate closer collaboration between humans and robots in various industries.

- Customization and Modularity: Future robotic-arms will offer greater customization options, allowing industries to tailor systems to specific needs and applications.

Implications for Industries:

- Manufacturing: Enhanced robotic-arms will lead to more flexible and efficient production lines, capable of adapting to changing demands and product variations.

- Healthcare: Advancements in robotic arm technology will improve surgical precision, patient care, and medical research capabilities.

- Logistics: Robotic arms will play a crucial role in automating material handling, sorting, and delivery processes, streamlining supply chains.

FAQs

Q1: What are collaborative robots?

A: Collaborative robots, or cobots, are robotic systems designed to work alongside human operators, enhancing productivity and safety in shared workspaces.

Q2: How does AI enhance robotic arms?

A: Artificial Intelligence enables robotic-arms to learn from their environment, adapt to new tasks, and improve performance over time, leading to increased efficiency and precision.

Q3: What is a mobile manipulator?

A: A mobile manipulator combines the mobility of an autonomous mobile robot with the dexterity of a robotic arm, allowing it to perform tasks in dynamic environments.

Q4: How are robotic arms becoming more energy-efficient?

A: Robotic arms are incorporating technologies such as regenerative braking systems, lightweight materials, and efficient motors to reduce energy consumption and environmental impact.

Q5: What does the future hold for robotic arms?

A: The future of robotic-arms includes advancements in AI integration, human-robot collaboration, and customization, leading to more versatile and efficient systems across various industries.

Conclusion

Robotic arms have evolved from rigid, task-specific machines into adaptable systems that combine intelligence, precision, and efficiency. Their role in automation is no longer limited to high-volume manufacturing lines but extends into healthcare, logistics, and other industries where flexibility and safety are essential. With trends like collaborative robots, AI-driven learning, advanced sensing, and mobile manipulators, these technologies are set to become the backbone of smart factories and service operations.

Equally important is the emphasis on sustainability and energy efficiency, which ensures that businesses can pursue automation without compromising environmental goals. As industries adopt greener practices, robotic-arms will help reduce waste, optimize energy use, and extend equipment lifespans.

The path forward points to tighter integration with IoT, greater customization, and stronger collaboration between humans and machines. For companies looking to remain competitive, keeping track of these advancements is no longer optional—it’s a necessity.

In summary, robotic-arms are not just tools of automation; they are enablers of long-term industrial transformation, driving productivity, safety, and innovation at scale.