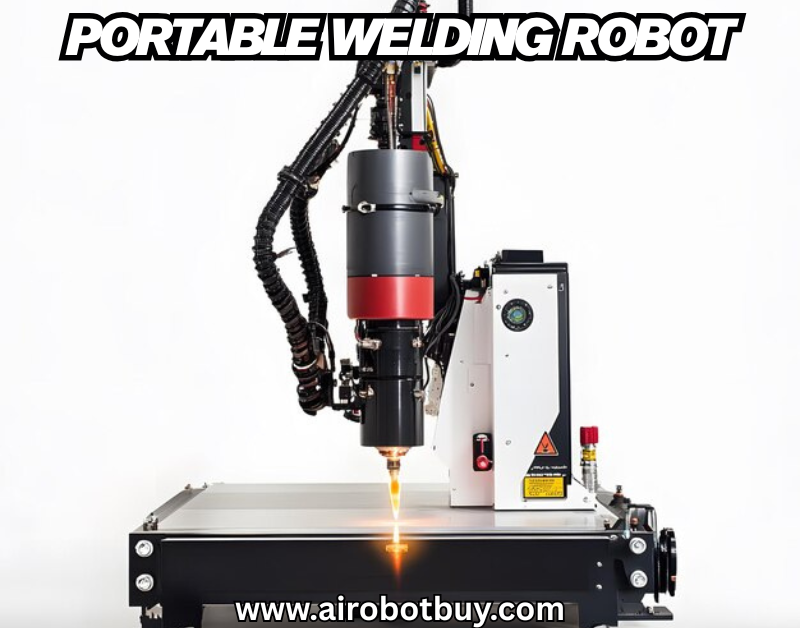

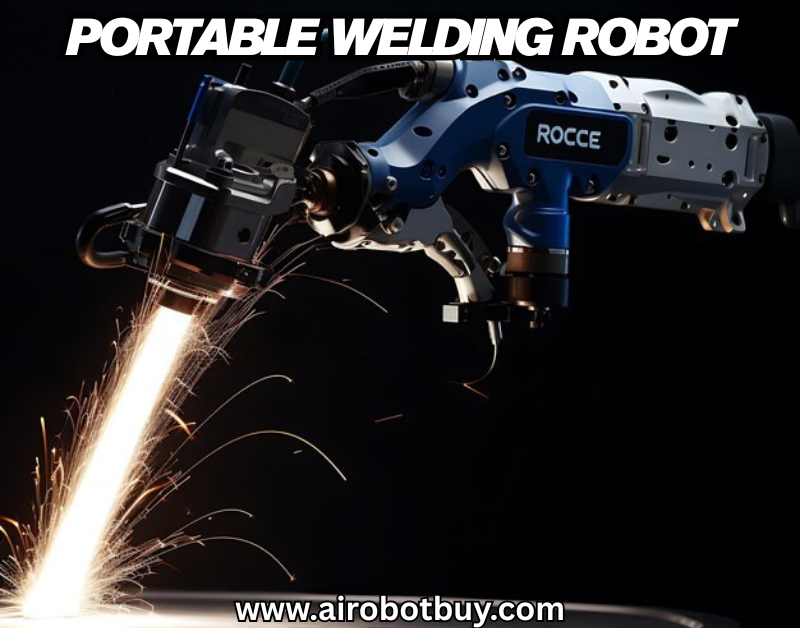

Welding plays a vital role in many industries, from manufacturing and construction to shipbuilding and automotive repair. Traditional welding methods, often relying on manual labor, have served the industry for decades. However, they come with limitations such as inconsistent quality, slower production speeds, and safety risks to workers. As technology advances, the introduction of portable welding robot has begun to transform how welding tasks are performed.

These robots combine automation with mobility, allowing welding to take place efficiently in various locations without the need for large fixed setups. A portable-welding-robot delivers consistent weld quality, increases productivity, and improves safety by reducing human exposure to welding hazards. With the flexibility to adapt to different welding processes and environments, these robots offer practical solutions for businesses seeking to modernize their operations.

Portable Welding Robot Advantages Over Traditional Welding Methods

In this guide, we will explain the key advantages of portable-welding-robot over traditional welding methods, highlighting how they improve efficiency, quality, safety, costs, flexibility, and environmental impact.

What is a Portable Welding Robot?

A portable-welding-robot is a mobile robotic system designed to automate welding tasks while being easily moved to different work locations. Unlike fixed robotic arms attached to production lines, portable-welding-robot come with wheels, compact frames, or lightweight structures that allow operators to reposition them quickly. This mobility is valuable in environments where welding needs vary across different parts or sites, such as construction yards, shipbuilding, or maintenance workshops. Visit here!

Key characteristics of a portable welding robot include:

- Mobility: Easy to transport and operate in various locations.

- Programmability: Ability to perform different welding tasks by changing programs.

- Automation: Robotic control of welding parameters like speed, angle, and heat.

- Compact size: Smaller footprint compared to fixed robotic welding stations.

Because of these features, portable welding robots offer a flexible and efficient solution for companies looking to automate welding without the restrictions of fixed installations.

Efficiency Gains

One of the most significant advantages of a portable-welding-robot is the increase in welding efficiency compared to traditional manual welding.

Faster Welding Speeds

- Portable welding robot maintain a consistent speed and feed rate during welding, which optimizes penetration and joint quality.

- Human welders often slow down due to fatigue, awkward positions, or breaks, but robots keep steady progress.

- This speed consistency reduces overall welding time and boosts daily production.

Continuous Operation

- Robots can run for extended hours, often across multiple shifts, without the need for rest.

- Unlike manual welders, portable-welding-robot do not experience fatigue, eliminating downtime caused by breaks or shift changes.

- This uninterrupted operation means more parts welded per day without increasing labor costs.

Reduced Setup Time

- Portable-welding-robot are designed for quick setup and repositioning.

- Less time spent preparing for each weld job means higher overall productivity.

Summary of Efficiency Gains:

| Efficiency Aspect | Portable-Welding-Robot | Traditional Welding |

|---|---|---|

| Welding Speed | Consistent and up to 30% faster | Variable, slower due to fatigue |

| Operating Hours | Continuous, multiple shifts | Limited by human endurance |

| Setup and Changeover Time | Quick and flexible | Longer due to manual setup |

Improved Welding Quality and Consistency

Quality control is critical in welding, and portable welding robots improve quality through automation and precision.

Repeatability

- Robots execute the same welding pattern over and over with minimal variation.

- This consistency lowers the risk of weld defects like cracks, porosity, and lack of fusion.

- Automated control of heat and speed ensures uniform weld beads.

Precision in Difficult Positions

- Portable-welding-robot excel in welding tight spots or complex angles that challenge human welders.

- Their robotic arms maintain steady positioning, improving weld accuracy.

Less Human Error

- Human welders may unintentionally deviate from weld parameters due to fatigue or distractions.

- Robots eliminate this variability by following programmed instructions precisely.

Improved Inspection Results

- Consistent welds reduce rejection rates in quality inspections.

- This leads to fewer repairs and saves materials and time.

Summary of Quality Advantages:

| Quality Aspect | Portable-Welding-Robot | Traditional Welding |

|---|---|---|

| Repeatability | High, with programmed precision | Variable, dependent on operator |

| Weld Defects | Lower rate due to automation | Higher due to human error |

| Complex Position Welding | Accurate, steady robotic positioning | Challenging for manual welders |

Enhanced Safety for Welders

Safety is a major concern in welding, and using a portable-welding-robot helps reduce risks associated with traditional methods.

Reduced Exposure to Hazards

- Robots perform the welding while operators control the system remotely.

- This lowers welder exposure to extreme heat, UV light, and toxic fumes.

- Operators can stay in safer zones away from sparks and smoke.

Safer Work in Hazardous Environments

- Portable-welding-robot can operate in confined spaces, at heights, or outdoors where conditions might be dangerous for people.

- Using robots in these situations reduces the chance of accidents or injuries.

Lower Fatigue and Stress

- Manual welding often requires awkward positions, causing fatigue or strain.

- Robots take over repetitive and strenuous tasks, improving overall workplace health.

Summary of Safety Benefits:

| Safety Aspect | Portable Welding Robot | Traditional Welding |

|---|---|---|

| Operator Exposure | Minimal, remote operation | Direct exposure to hazards |

| Operation in Dangerous Areas | Robot can be deployed safely | Risky for human welders |

| Physical Strain | Reduced, less manual effort | High, with repetitive movements |

Cost Benefits Over Time

While portable welding robots require upfront investment, they offer significant cost advantages compared to traditional welding methods.

Reduced Labor Costs

- Automation reduces the number of manual welders needed.

- This cuts direct wages, benefits, and overtime expenses.

- Operators oversee multiple robots or processes rather than performing all welding themselves.

Lower Rework and Scrap Costs

- Consistent quality means fewer defective welds.

- Reduced defects translate to less wasted material and labor for repairs.

Maintenance and Consumables Savings

- Robots operate with optimal parameters, avoiding damage to welding tips and torches.

- This careful use extends consumable life and reduces replacement frequency.

Long-Term Return on Investment (ROI)

- Many companies see ROI within 1-3 years due to efficiency and quality improvements.

- Savings continue growing as production scales up.

Summary of Cost Benefits:

| Cost Aspect | Portable Welding Robot | Traditional Welding |

|---|---|---|

| Labor Costs | Lower due to automation | Higher with manual labor |

| Rework and Scrap Costs | Reduced by up to 25% | Higher due to inconsistent welds |

| Consumables Wear | Optimized, longer life | Frequent replacement |

Flexibility and Mobility

A key advantage of a portable welding robot is its ability to adapt to various tasks and environments.

On-Site Welding

- Portable robots can be brought directly to construction sites or large assemblies.

- This eliminates the need to transport heavy parts to a fixed welding station.

Multi-Task Capability

- Portable-welding-robot can perform different welding processes such as MIG, TIG, or arc welding by swapping torches or changing programming.

- They adapt easily to various product sizes and shapes.

Easy Integration

- These robots fit into existing workflows without requiring extensive factory modifications.

- Their compact size means they can operate in smaller workshops or crowded spaces.

Summary of Flexibility:

| Flexibility Aspect | Portable Welding Robot | Traditional Welding |

|---|---|---|

| Mobility | Easily moved between sites and tasks | Fixed or limited mobility |

| Welding Process Variety | Supports multiple welding types | Typically specific to one process |

| Workspace Integration | Minimal setup, compact design | Requires dedicated stations |

User-Friendly Operation and Programming

Modern portable-welding-robot are designed for ease of use, even for operators without advanced robotics training.

Intuitive Programming Interfaces

- Many portable welding robots come with teach pendants or touchscreens.

- Operators can record welding paths manually or select pre-set programs.

- This reduces training time and helps operators adjust welding parameters easily.

Remote Monitoring

- Some models offer connectivity to monitor weld quality and robot status in real time.

- Remote diagnostics reduce downtime and speed up troubleshooting.

Reduced Skill Barrier

- User-friendly software means companies don’t need highly specialized staff.

- This broadens the pool of potential operators and lowers training costs.

Summary of User-Friendliness:

| User Aspect | Portable-Welding-Robot | Traditional Welding |

|---|---|---|

| Programming Ease | Intuitive interfaces, teach pendants | Manual skill-based |

| Monitoring | Remote monitoring available | On-site manual supervision |

| Training Time | Shorter due to simplified controls | Longer due to skill complexity |

Environmental Impact

Portable welding robots can also help companies reduce their environmental footprint.

Energy Efficiency

- Robots optimize power consumption during welding.

- Steady welding reduces unnecessary energy spikes common with manual welding.

Reduced Fumes and Waste

- Consistent welding parameters decrease spatter and smoke.

- Better weld quality leads to less scrap material.

Compliance with Environmental Standards

- Automated systems help companies meet stricter workplace air quality and emissions regulations.

Summary of Environmental Impact:

| Environmental Aspect | Portable Welding Robot | Traditional Welding |

|---|---|---|

| Energy Consumption | Optimized, lower overall | Higher due to inconsistent welds |

| Emissions | Reduced fumes and spatter | More smoke and waste |

| Regulatory Compliance | Easier to meet standards | Challenging to control |

Summary Table: Portable Welding Robot vs Traditional Welding

| Feature | Portable Welding Robot | Traditional Welding |

|---|---|---|

| Welding Speed | 20-30% faster, consistent | Variable, slower |

| Operating Hours | Continuous, multi-shift | Limited by human fatigue |

| Weld Quality & Consistency | High repeatability, fewer defects | Variable, operator-dependent |

| Safety | Lower operator risk, remote operation | Direct exposure to hazards |

| Labor Costs | Reduced via automation | Higher due to manual labor |

| Rework and Scrap Costs | Lower due to consistent welds | Higher due to errors |

| Mobility & Flexibility | Portable, versatile | Fixed or limited |

| Programming Ease | User-friendly, teach pendants | Manual skill-based |

| Environmental Impact | Lower energy use, emissions | Higher energy, more fumes |

Frequently Asked Questions (FAQs)

Q1: Are portable welding robot suitable for small workshops?

Yes. Models come in various sizes and capacities, making them accessible for small and medium-sized businesses.

Q2: How much training is needed to operate one?

Basic operation training can be completed in days thanks to user-friendly interfaces.

Q3: Can portable welding robot replace all manual welding tasks?

Not always. They excel at repetitive, precise welding jobs but may not fully replace manual welding for complex or one-off tasks.

Q4: How often do portable welding robot require maintenance?

Routine maintenance includes inspection of welding torches, joints, and software updates, generally done monthly or per manufacturer guidelines.

Conclusion

The rise of the portable welding robot marks a significant shift in how welding is approached across industries. By combining automation with mobility, these robots address many challenges faced by traditional welding methods. They deliver faster welding speeds, consistent high-quality welds, and enhanced safety by minimizing direct human exposure to hazardous environments. Over time, portable-welding-robot also help reduce labor costs, lower material waste, and improve overall operational efficiency. Their flexibility allows them to be deployed in diverse settings—from factory floors to construction sites—without the limitations of fixed equipment. Additionally, user-friendly programming and remote monitoring capabilities make them accessible to a wider range of operators, reducing the training burden on companies. Environmentally, portable-welding-robots contribute to energy savings and lower emissions, supporting more sustainable welding practices. For any business aiming to boost productivity, improve weld quality, and ensure worker safety, investing in portable welding robot offers clear, measurable benefits. As welding technology continues to evolve, embracing portable-welding-robots is a practical step toward future-proofing your operations and staying competitive in a fast-changing industrial landscape.