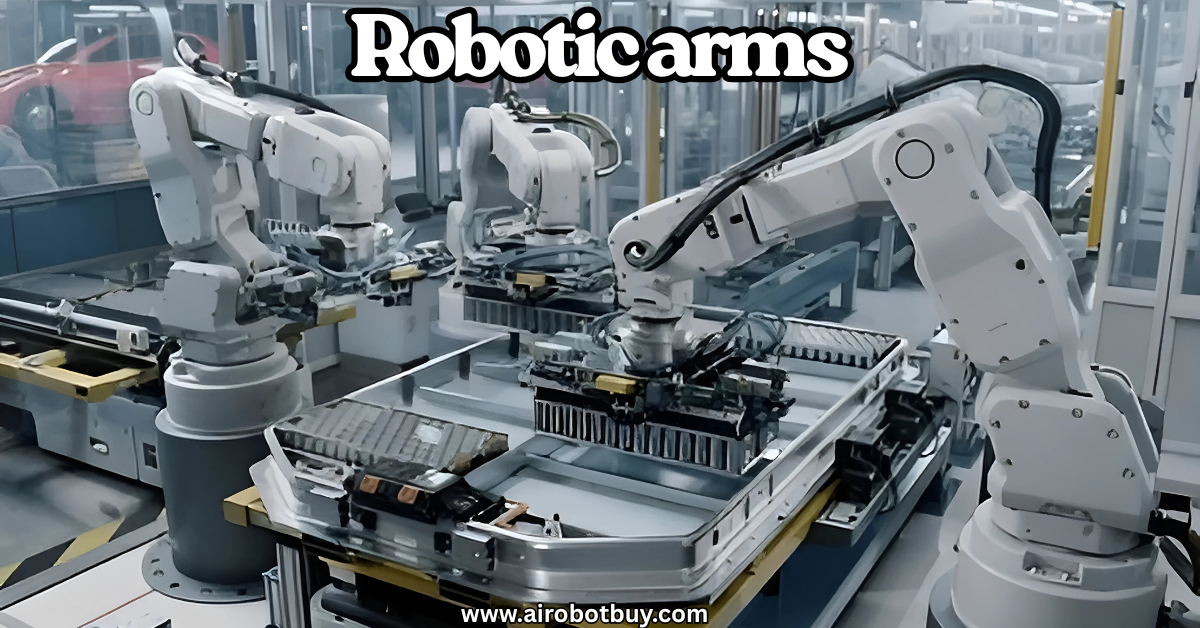

Industrial Robotics has become one of the most important forces shaping the future of business operations worldwide. Once limited to large-scale manufacturers, robotics is now being adopted by companies of all sizes because it offers a clear path to greater efficiency, reduced costs, and improved safety. The global market for industrial robotics was valued at over $70 billion in 2024, and forecasts show it could exceed $120 billion by 2030. That growth highlights a simple fact: robotics is no longer optional—it is becoming an essential part of competitive business strategies.

The impact of Industrial-Robotics can be seen across multiple areas. Robots increase productivity by working without breaks, improve quality through precision, and handle tasks that are either repetitive or hazardous for human workers. At the same time, advances in artificial intelligence, IoT integration, and new service models are making robotics more accessible than ever before.

Industrial Robotics Future Trends Every Business Should Know

In this guide we will explain the future trends in Industrial Robotics every business should know and how they are reshaping industries today.

Why Industrial Robotics Matters Now

Industrial-Robotics has shifted from being an advanced option for only a few industries to becoming a core element of modern business operations. The global market for industrial robotics reached $70 billion in 2024, and projections indicate it could exceed $120 billion by 2030. This growth reflects a larger movement—businesses of all sizes are realizing that robotics is not just about automation, but also about staying competitive. Visit here!

Industrial Robotics helps companies:

- Reduce costs by automating repetitive processes.

- Improve efficiency by working continuously without breaks.

- Enhance product quality with consistent precision.

- Strengthen safety by reducing human exposure to dangerous tasks.

For businesses, understanding the latest trends in Industrial Robotics is critical. The future is not about whether robots will be used, but how quickly and effectively they are adopted.

Collaborative Robots (Cobots) Becoming Mainstream

Collaborative robots, or cobots, are one of the most visible trends in Industrial-Robotics. Unlike traditional robots that require safety cages, cobots are designed to work directly alongside humans. They are safer, more flexible, and easier to program.

Key facts about cobots in Industrial Robotics:

- Cobots represented about 7% of global industrial robot sales in 2023, but adoption is projected to rise to 30% by 2030.

- They are most commonly used in assembly, packaging, and light manufacturing.

- Their smaller size and user-friendly programming make them accessible to small and medium-sized enterprises (SMEs).

Business benefits:

- Lower entry costs compared to heavy-duty robots.

- Ability to quickly reprogram for different tasks.

- Improved productivity in shared human-robot workflows.

For many businesses, cobots are the first step into Industrial Robotics because they offer both safety and flexibility without requiring a full factory redesign.

Artificial Intelligence Driving Smarter Robots

Artificial Intelligence (AI) is transforming Industrial-Robotics into something far more powerful than repetitive automation. Robots with AI capabilities can learn, adapt, and improve performance based on data.

AI integration allows robots to:

- Detect and correct quality issues in real time.

- Adjust workflows based on changing production requirements.

- Support predictive maintenance by analyzing machine health.

Industry data shows that over 40% of industrial robots shipped in 2024 included AI-enabled features, and the percentage is expected to grow sharply in the next five years.

Business benefits:

- Reduced waste through early detection of defects.

- More flexibility in handling customized or small-batch production.

- Extended machine lifespan due to predictive maintenance.

AI is shaping the future of Industrial Robotics by enabling robots to work intelligently rather than mechanically, opening new possibilities in every sector from electronics to automotive.

Industrial Robotics Integrated with IoT

The Industrial Internet of Things (IIoT) is a game-changer for Industrial-Robotics. When robots are connected with sensors, networks, and cloud systems, businesses gain real-time data visibility across operations.

Integration with IoT allows robots to:

- Share operational data with other machines.

- Provide live updates on performance and maintenance needs.

- Optimize production speed and reduce unplanned downtime.

Studies reveal that companies adopting IoT-enabled Industrial-Robotics can improve overall equipment effectiveness (OEE) by up to 20%.

Business benefits:

- Better decision-making through data insights.

- More accurate production planning and forecasting.

- Faster response to changes in demand or disruptions.

For modern factories, IoT-connected robots are not a luxury—they are essential for achieving smart manufacturing.

Human-Robot Collaboration in Logistics

Industrial Robotics is no longer limited to production floors. Logistics is now one of the fastest-growing areas of robot adoption. Autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) are transforming how goods are moved, stored, and shipped.

Logistics robotics is growing because:

- Over 50% of warehouses worldwide are expected to use robotic automation by 2030.

- Robots can increase picking speed and accuracy by up to 40%.

- E-commerce growth is driving demand for faster fulfillment.

Business benefits:

- Reduced labor shortages in warehousing and distribution.

- Improved customer satisfaction through faster deliveries.

- Scalable solutions to match seasonal demand changes.

This trend highlights how Industrial-Robotics is expanding beyond traditional manufacturing into service and supply chain industries.

Robotics-as-a-Service (RaaS) Lowering Barriers

One of the biggest challenges with Industrial Robotics has always been the high upfront cost. Robotics-as-a-Service (RaaS) changes this by offering robots on subscription or rental models. Businesses pay for usage rather than full ownership.

Key points about RaaS:

- The RaaS market is expected to grow at 15% CAGR through 2030.

- Providers handle setup, maintenance, and software updates.

- It allows companies to scale usage up or down depending on demand.

Business benefits:

- Lower financial risk when adopting Industrial-Robotics.

- Faster return on investment since capital costs are reduced.

- Easier adoption for SMEs that could not afford robots before.

RaaS is democratizing Industrial Robotics, making it accessible to companies of all sizes.

Focus on Energy Efficiency and Sustainability

Sustainability has become a major priority for businesses, and Industrial Robotics is playing a role in helping companies reduce waste and energy use.

Robots contribute to sustainability by:

- Consistently using less energy per unit of output.

- Reducing material waste by increasing precision.

- Supporting greener production with optimized workflows.

McKinsey research shows that factories using energy-efficient robots can cut energy consumption by 20–30%.

Business benefits:

- Lower operating costs through energy savings.

- Compliance with stricter environmental regulations.

- Stronger reputation with eco-conscious consumers.

Sustainability is not optional anymore, and Industrial Robotics offers a practical solution for businesses to achieve efficiency and environmental goals together.

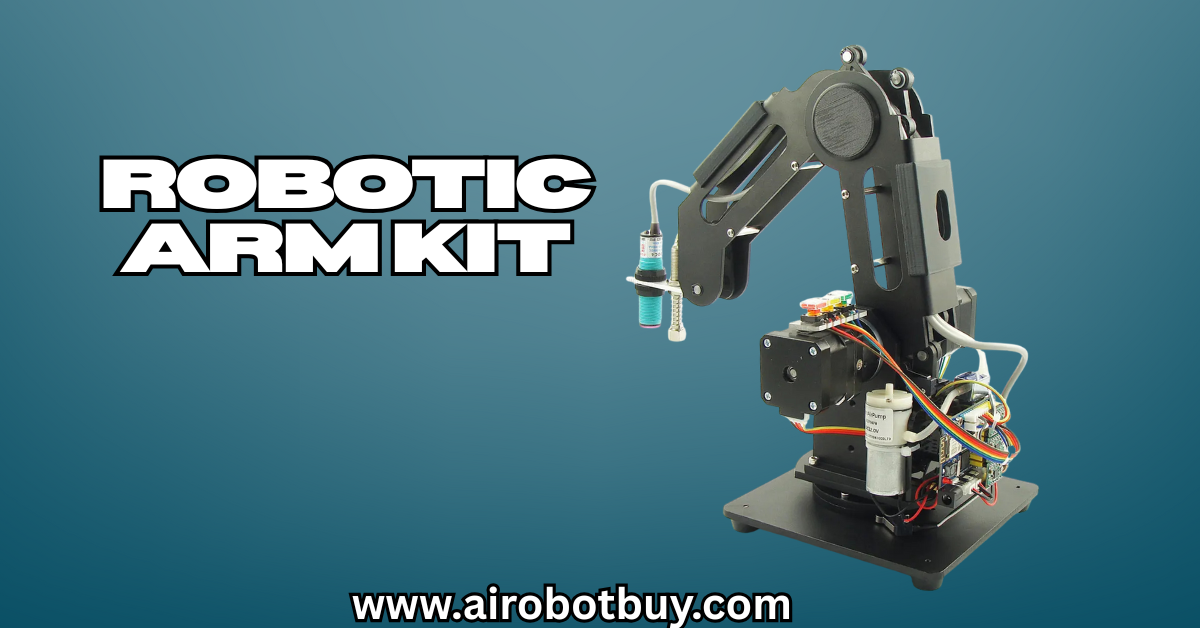

Advanced Vision Systems Expanding Applications

Modern Industrial Robotics is equipped with advanced machine vision systems that allow robots to “see” and process their environment with high precision. These systems use cameras, sensors, and AI-based recognition.

Capabilities of vision-enabled robots:

- Inspecting parts for defects.

- Guiding robotic arms for complex assembly.

- Handling delicate or irregularly shaped materials.

The market for vision-guided Industrial-Robotics is expected to reach $15 billion by 2027.

Business benefits:

- Greater precision in high-value industries like electronics and pharmaceuticals.

- Reduced human error in visual inspections.

- Expanded automation in previously manual tasks.

By giving robots the ability to see and respond, vision systems significantly increase the range of tasks Industrial Robotics can perform.

5G Connectivity Boosting Robotics Performance

Fast, reliable connectivity is vital for next-generation Industrial-Robotics. With 5G technology, robots can communicate faster, process more data in real time, and operate more flexibly.

Benefits of 5G for Industrial Robotics include:

- Ultra-low latency (as low as 1 millisecond).

- Real-time data transfer for cloud-based robotics control.

- Seamless coordination of multiple robots across large facilities.

Business benefits:

- Improved production line flexibility.

- Reliable performance in smart factories.

- Ability to scale mobile robotics across sites.

As 5G networks expand globally, their impact on Industrial-Robotics will only grow, enabling smarter and more connected automation systems.

Workforce Upskilling for Robotics Integration

The rise of Industrial Robotics does not eliminate the need for human workers—it changes their roles. Employees are required to manage, program, and maintain robots.

Key workforce trends:

- The World Economic Forum estimates that 50% of workers will need reskilling by 2025 due to automation.

- Training programs in robotics programming and maintenance are rapidly increasing.

- Businesses investing in workforce upskilling see smoother adoption and less resistance.

Business benefits:

- Reduced downtime through on-site technical expertise.

- Better collaboration between workers and robots.

- Long-term workforce stability as skills evolve with technology.

Upskilling ensures that Industrial Robotics complements rather than disrupts the workforce.

Industrial-Robotics in Small and Medium Businesses

Historically, Industrial-Robotics was limited to large enterprises with big budgets. Today, thanks to cobots, RaaS, and simplified programming, small and medium-sized businesses (SMEs) are rapidly joining the robotics revolution.

Adoption trends:

- In 2023, 35% of new industrial robot installations were in SMEs, compared to just 10% five years earlier.

- SMEs use robots for tasks like packaging, welding, assembly, and material handling.

Business benefits:

- More affordable access to advanced automation.

- Enhanced competitiveness against larger players.

- Localized, flexible production options.

The growing adoption of Industrial Robotics in SMEs signals that robotics is no longer exclusive—it’s becoming universal.

Comparison Table: Key Trends at a Glance

| Trend | Impact on Business | Growth Timeline |

|---|---|---|

| Cobots | Affordable, safe, flexible automation | Growing rapidly through 2030 |

| AI in Robotics | Smarter decision-making, reduced waste | Scaling now |

| IoT Integration | Real-time monitoring, predictive maintenance | Expanding in 2025+ |

| Logistics Robotics | Faster order fulfillment, labor efficiency | Mainstream by 2030 |

| RaaS | Lower entry cost, easy scaling | Accelerating adoption |

| Sustainability | Reduced energy and material waste | Crucial by 2030 |

| Vision Systems | Higher precision, wider applications | Fast adoption |

| 5G Connectivity | Real-time data transfer, scalability | Expanding with 5G rollout |

| Workforce Upskilling | Better adoption, fewer disruptions | Ongoing need |

| SME Adoption | Wider accessibility, local competitiveness | Rapid growth |

Frequently Asked Questions (FAQ)

Q1. What industries are leading in Industrial-Robotics adoption?

Manufacturing, automotive, electronics, food processing, and logistics are at the forefront.

Q2. Are Industrial-Robotics solutions affordable for small businesses?

Yes. Cobots, simplified systems, and Robotics-as-a-Service have made adoption practical for SMEs.

Q3. How long does it take to see ROI from Industrial-Robotics?

Typically within 1–3 years, depending on the application and scale of deployment.

Q4. Do robots replace workers completely?

No. Industrial Robotics takes over repetitive and dangerous tasks while creating new roles in programming, supervision, and maintenance.

Q5. Is Industrial-Robotics environmentally friendly?

Yes. Energy-efficient robots reduce consumption and waste, supporting sustainability goals.

Conclusion

Industrial Robotics is no longer just a tool for automation—it has become a foundation for long-term business growth. From collaborative robots and AI-driven intelligence to IoT connectivity, 5G integration, and Robotics-as-a-Service, the technology is expanding in ways that make it accessible to businesses of all sizes. What was once a high-cost solution for large manufacturers is now transforming logistics, small enterprises, and even service industries.

The benefits are clear: higher efficiency, reduced errors, improved safety, and stronger adaptability in fast-changing markets. At the same time, Industrial Robotics supports sustainability by lowering energy use and minimizing waste, helping businesses align with global environmental goals. Workforce upskilling is also ensuring that humans and robots complement one another rather than compete.

The message for businesses is straightforward: adopting Industrial-Robotics is not a matter of if, but when. Companies that move forward now will position themselves for greater resilience, competitiveness, and innovation in the years ahead.