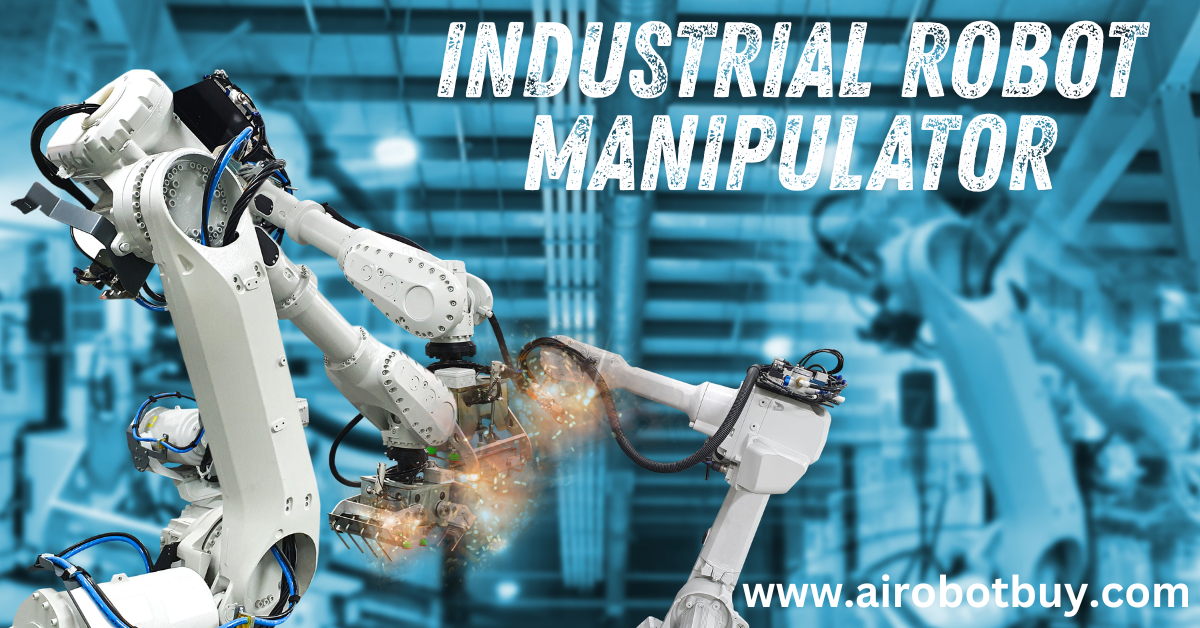

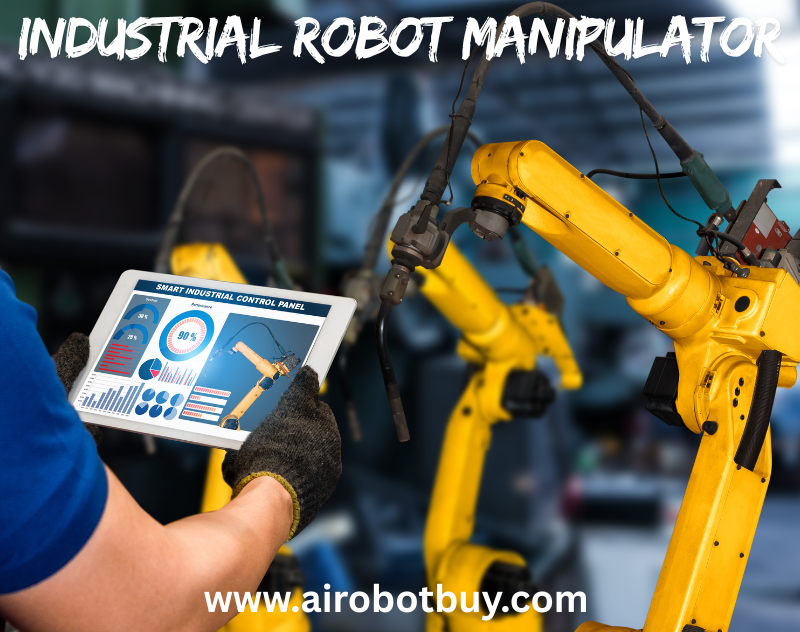

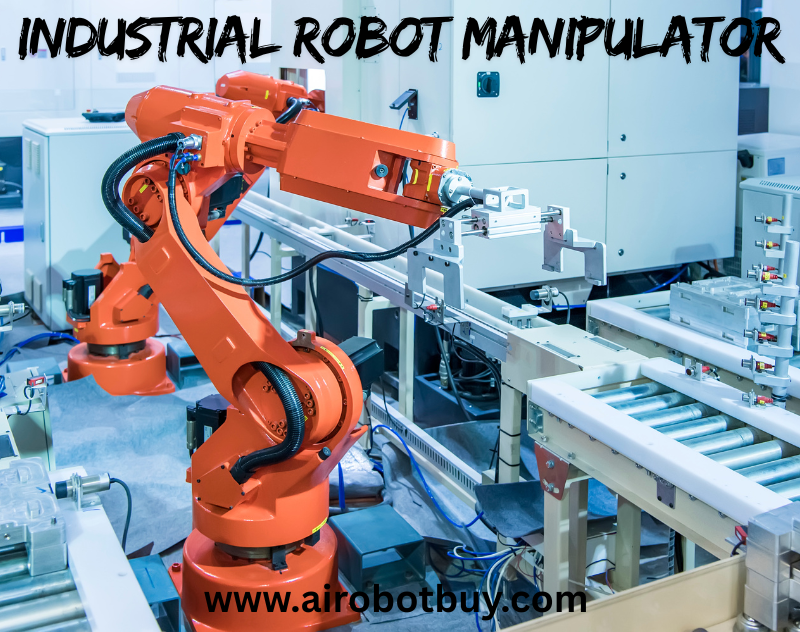

In today’s fast-changing industrial landscape, efficiency isn’t just a goal—it’s a requirement. As global supply chains face pressure to deliver faster, cheaper, and with greater consistency, companies across industries are turning to automation as a practical solution. At the center of this transformation is the Industrial Robot Manipulator—a mechanical workhorse built to handle repetitive, precise, and sometimes dangerous tasks. These machines are no longer limited to massive automotive plants or high-budget tech companies. They are now being integrated by small and mid-sized manufacturers as well, thanks to advancements in affordability and ease of use.

An Industrial Robot Manipulator offers more than just mechanical movement. It brings measurable gains in speed, accuracy, and safety while reducing long-term operational costs. Whether you’re assembling electronics, packaging food products, or streamlining warehouse operations, these systems are reshaping what’s possible in automation.

Industrial Robot Manipulator Benefits That Are Revolutionizing Automation Today

In this guide, we will explain what industrial robot manipulators are, why they’re gaining adoption, the industries that benefit the most, challenges you should be aware of, and what the future holds for this essential automation tool.

In the current age of rapid manufacturing evolution, the use of automation is not just a trend but a necessity. The Industrial Robot Manipulator has become central to this transformation. As companies face global competition, rising labor costs, and the pressure to meet growing consumer demands, robot manipulators provide a consistent and scalable solution. These machines are designed to perform repetitive, dangerous, or highly precise tasks that would be either unsafe or inefficient for human workers. With industries focusing more on lean manufacturing, robotics offers the ability to reduce waste, streamline operations, and increase output without expanding physical labor resources. Visit here!

What is an Industrial Robot Manipulator?

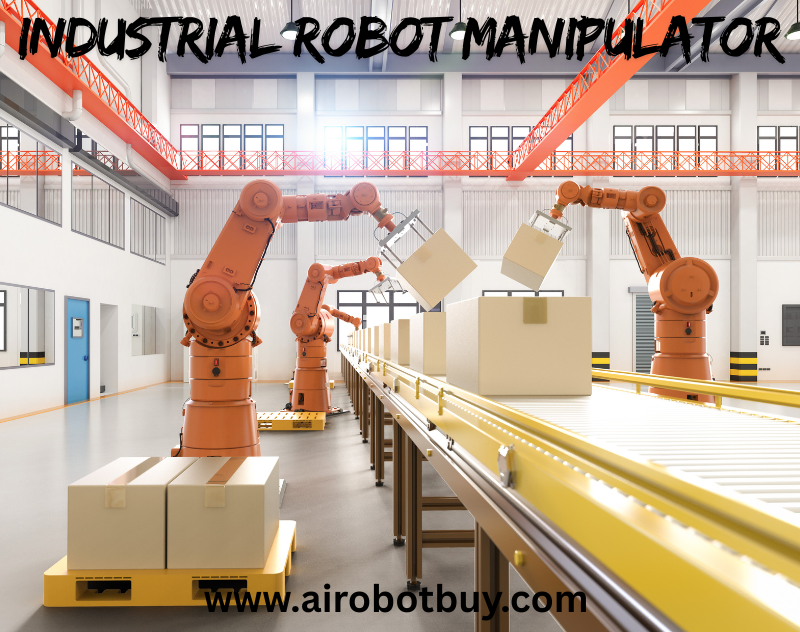

An Industrial Robot Manipulator is a programmable mechanical device used in manufacturing environments to move, handle, or assemble parts with high accuracy. It generally resembles a human arm, consisting of several joints and links that provide a wide range of motion. The manipulator can be outfitted with various tools or end-effectors, such as grippers, welding torches, or suction cups, depending on the task. These robots are typically controlled through a central computer or control system, allowing them to repeat tasks with high precision. They come in several configurations, including articulated, SCARA, delta, and Cartesian robots, each suitable for different industrial tasks.

The Benefits That Are Driving Adoption

The rise in the use of Industrial Robot Manipulator systems is driven by a wide array of practical advantages that align with industrial objectives:

- Speed and Productivity: Robot manipulators can operate continuously without breaks, delivering higher throughput compared to manual labor. This leads to faster cycle times and greater production volume.

- Accuracy and Repeatability: These robots are capable of performing tasks with micrometer-level precision, which reduces errors and ensures consistent product quality.

- Cost Efficiency: Although the initial investment is substantial, the long-term savings on labor, errors, and downtime often outweigh the cost. Maintenance and programming costs are also predictable and scalable.

- Safety Improvements: Dangerous tasks such as handling heavy parts, working in hazardous environments, or exposure to toxic substances are delegated to robot manipulators, reducing the risk to human workers.

- Flexible Automation: Modern robot manipulators can be reprogrammed and retooled for different applications, making them highly adaptable for companies with varied product lines or frequent changes in demand.

Comparison of Manual Labor vs Industrial Robot Manipulator

| Factor | Manual Labor | Industrial Robot Manipulator |

|---|---|---|

| Operation Time | 8 hrs/day | 24/7 Continuous |

| Error Rate | Variable | Consistently Low |

| Safety Risk | High | Low |

| Precision Level | Moderate | High |

| Cost Over Time | Increasing | Decreasing |

| Flexibility in Task | Limited | High |

Real-World Industries Benefiting the Most

Industrial Robot Manipulator systems are now used in a variety of industries, each leveraging the benefits in different ways:

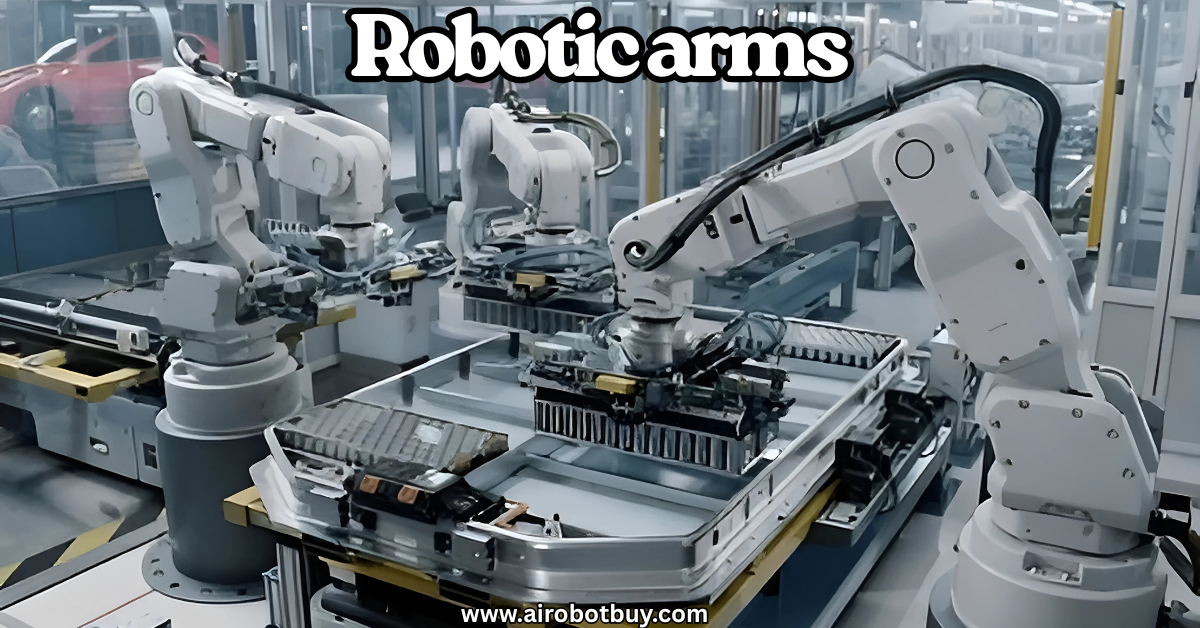

- Automotive Industry: From welding and painting to assembling components, robot manipulators perform tasks that require consistency and durability.

- Electronics Manufacturing: With delicate components and small parts, electronic assembly demands precision, which is easily achieved by SCARA and Cartesian robots.

- Food and Beverage: Robots are used for packaging, sorting, and palletizing to meet hygiene standards and fast-paced distribution demands.

- Pharmaceuticals: In cleanroom environments, robot manipulators assist in packaging and sorting medicines while ensuring sterile conditions.

- Logistics and Warehousing: Robots help in picking, sorting, and transporting goods with minimal error and high speed, especially in e-commerce operations.

Use Cases by Industry

| Industry | Common Tasks with Industrial Robot Manipulator |

| Automotive | Welding, Painting, Assembly |

| Electronics | PCB Assembly, Soldering, Inspection |

| Food & Beverage | Packaging, Sorting, Palletizing |

| Pharmaceuticals | Sterile Packaging, Lab Sample Handling |

| Logistics | Order Picking, Palletizing, Sorting |

Challenges to Be Aware Of

While the benefits are clear, companies must also consider the practical challenges associated with deploying an Industrial Robot Manipulator:

- High Initial Cost: Robots, especially advanced models, can be expensive to purchase and install. ROI is typically long-term.

- Workforce Training: Skilled personnel are required to program, operate, and maintain these systems. Lack of training can delay integration.

- Integration with Existing Systems: Compatibility with legacy machinery and systems can pose difficulties during implementation.

- Maintenance Needs: Though generally reliable, robot manipulators still require regular upkeep, including software updates and hardware calibration.

- Cybersecurity Risks: As industrial robots are increasingly connected to networks, they are vulnerable to digital threats if not properly secured.

Common Industrial Robot Manipulator Challenges and Mitigations

| Challenge | Mitigation Strategy |

| High Cost | Government subsidies, phased implementation |

| Skill Shortage | Staff training, hiring automation engineers |

| Integration Issues | Use of middleware, vendor consultation |

| Maintenance Complexity | Predictive maintenance tools |

| Cybersecurity | Network segmentation, regular software updates |

The Future of Robot Manipulators in Automation

The development of the Industrial Robot Manipulator is moving rapidly. As technology becomes more accessible and intelligent, the capabilities of these systems will expand.

- Collaborative Robots (Cobots): Designed to work alongside humans, cobots are becoming popular in small and medium enterprises. They are safer, easier to program, and cost less than traditional robots.

- AI and Machine Learning: Robots are being equipped with machine vision and AI-based decision-making, allowing them to adapt to changes in the environment or tasks in real-time.

- No-Code Programming: Drag-and-drop interfaces and user-friendly programming tools are reducing the need for advanced programming skills.

- Predictive Maintenance: Using sensors and IoT data, companies can predict when parts will fail and schedule maintenance proactively, reducing downtime.

- Lower Costs and Broader Access: The cost of acquiring robot manipulators is gradually decreasing, making them a viable option for businesses of all sizes.

Q&A Section

Q: Can small businesses benefit from using Industrial Robot Manipulators?

A: Yes, many robot models are now affordable and designed for small-scale operations. Cobots especially offer low-cost entry with quick deployment.

Q: Are robot manipulators difficult to program?

A: Modern systems often feature intuitive interfaces, and many vendors provide training. No-code solutions are also reducing complexity.

Q: What maintenance is required for Industrial Robot Manipulators?

A: Regular inspections, software updates, calibration, and preventive replacement of wearable parts are typical maintenance tasks.

Q: How do robot manipulators impact job opportunities?

A: They shift labor from manual, repetitive work to higher-value roles such as supervision, programming, and systems maintenance.

Q: Are these robots safe to use near humans?

A: Collaborative models are equipped with sensors and programmed to stop or slow down upon detecting human presence, enhancing safety.

Conclusion

The Industrial Robot Manipulator is no longer a futuristic concept—it’s a present-day solution delivering real impact across industries. From improving precision and speed to lowering costs and enhancing workplace safety, these machines offer clear, measurable advantages. As global manufacturing becomes more complex and customer demands evolve, the need for flexible, reliable, and scalable automation continues to rise.

What makes industrial robot manipulator truly valuable is their adaptability. They can be programmed for a wide range of tasks, easily retooled for different products, and scaled to match the needs of both small and large operations. And with newer technologies like collaborative robots, AI-driven vision systems, and simplified user interfaces, adoption is becoming easier and more affordable than ever.

Challenges like upfront cost and technical integration still exist, but they’re shrinking fast. Companies that take a proactive approach today—investing in the right equipment and training—are positioning themselves for long-term efficiency and resilience.