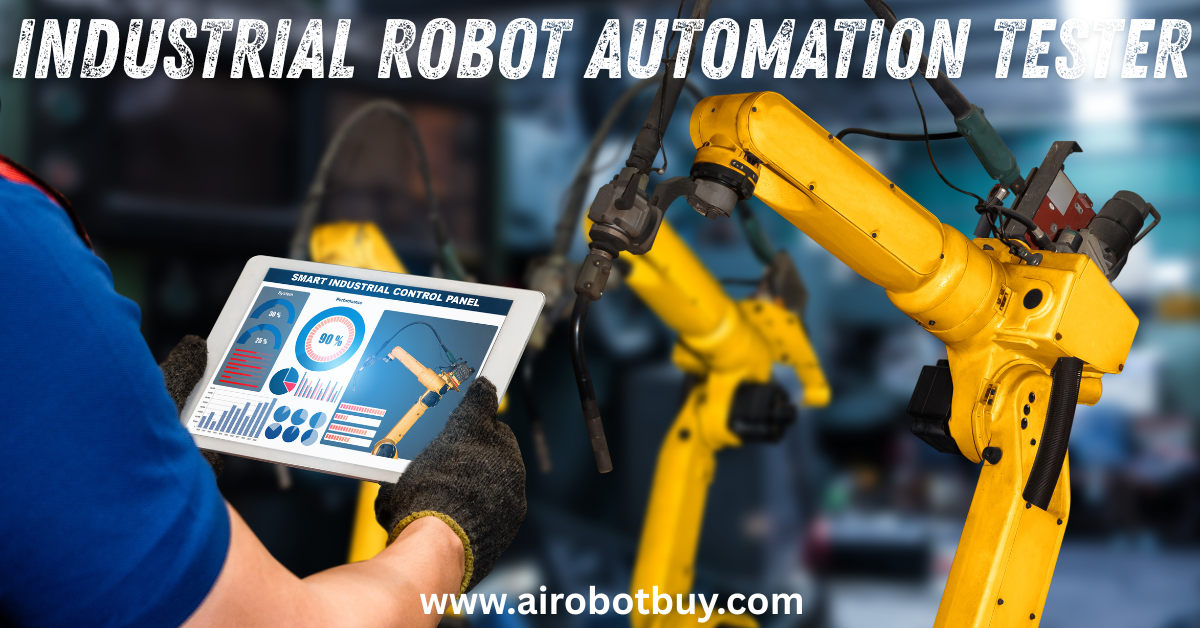

Even today’s modern factories are no longer being driven by mere human hands — they are powered by smart machines, particularly industrial robot automation tester, to ensure speed, accuracy, and 24/7 production. However, before all these robots can go on the production floor, they have to be thoroughly tested first. That is where the Industrial Robot Automation Tester comes in. This is not a job of simply doing software tests — it’s ensuring that the entire robotic system operates safely, reliably, and in real-time applications where even a millisecond of delay can be disastrous.

Industrial robot automation tester face a singular combination of challenges: hardware-software integration, safety standards, firmware uploads, no access to physical units, and sheer amounts of test data. This job is different from conventional software QA positions in that it requires cross-discipline skills, hands-on work with machines, and industrial protocol and safety standards knowledge.

With automation expanding across the auto, electronics, and logistics industries, and more, the need for skilled testers is on the rise. So are the technical issues they encounter daily in the workplace.

Here in this guide, we’ll be detailing the top 7 issues Industrial Robot Automation Testers encounter in today’s high-demand production environments — with real-world insights, tools, and testing strategies.

Industrial Robot Automation Tester Faces Top 7 Challenges in System Testing Today

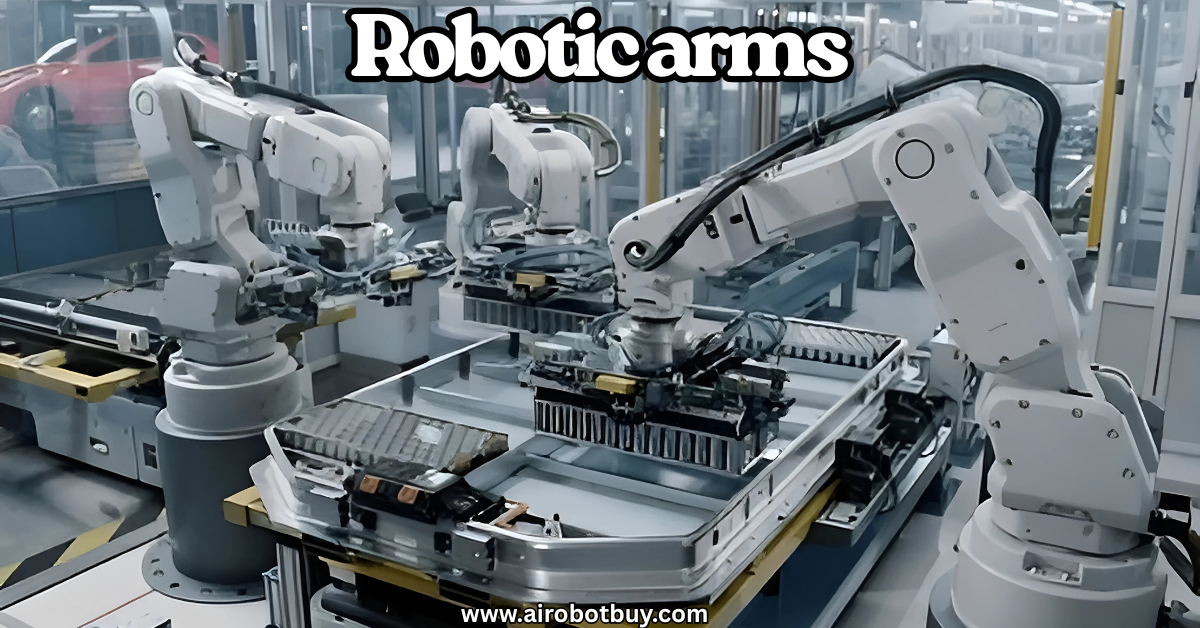

Industrial automation has taken over as the pillar of modern manufacturing, and robots are at the forefront of this revolution. The robots handle repeated tasks with high precision at high speeds with consistency. The challenge that remains is ensuring they work flawlessly and safely under any condition. That is the work of the Industrial Robot Automation Tester, whose responsibility is to test, verify, and certify robotic system functionality before and after roll-out.

The testing process isn’t merely a matter of checking whether or not a robot functions — it’s about confirming that it does so correctly, in real-time, without any threat to human labor or productivity goals. This blog names and defines the top 7 challenges for industrial robot automation testers, with exhaustive practical advice in each case. Visit here!

Complex Hardware and Software Integration

Industrial robot automation tester integrate mechanical, electrical, and software elements into one working entity. Testing involves verification of communication among sensors, actuators, PLCs, control algorithms, embedded systems, and external devices. One component failure generally has a series of system failures.

Primary Integration Components:

- Control algorithms should properly communicate with physical motion controllers.

- Sensor feedback needs to be processed in real time.

- Embedded firmware needs to be stable under changing load conditions.

Testing Tips:

- Employ Hardware-in-the-Loop (HIL) simulation facilities to integrate test prior to fully ready hardware.

- Verify all communication of data through communication protocols (e.g., EtherCAT, PROFINET).

- Apply automatic notifications for conflicting sensor-actuator feedback.

Tooling Options:

| Component | Suggested Tool |

|---|---|

| Sensor signal tracking | Oscilloscope, Logic Analyzer |

| Software debugging | JTAG, In-Circuit Emulator |

| Integration testing | National Instruments LabVIEW |

Restricted Physical Robot Access

Most testers work in the scenario where limited quantities of robot units are available, usually for access by multiple teams. Physical equipment can also be set aside for production purposes, such that it becomes challenging to conduct tests in quantity or consistently replicate errors.

Testing Challenges:

- Inability to run long-duration or high-volume tests.

- Limited access during production hours.

- Delays due to maintenance downtime or scheduling conflicts.

Solutions:

- Construct high-fidelity simulations through digital twin technologies.

- Build test benches with small models or off-cycle mockups.

- Make recordings of test sessions and recycle data for subsequent test cases.

Testing Alternatives:

| Environment | Use Case |

| Digital Twin | Full system behavior emulation |

| HIL Testing | Software validation without hardware |

| Simulators (ROS/Gazebo) | Motion and path planning checks |

Real-Time Processing and Latency Constraints

Industrial robot automation tester work on strict real-time constraints. Lag of a few milliseconds in command execution can produce deviations that impact performance or safety. This complicates testing.

Critical Areas to Validate:

- Control loop time consistency.

- Command signal transmission and execution.

- Interrupt handling in embedded systems.

Testing Approach:

- Measure latency at every step through diagnostic logging.

- Examine jitter and detect patterns in control loop execution.

- Use real-time operating system (RTOS) profilers to identify bottlenecks.

Latency Metrics Table:

| Task | Acceptable Delay (ms) |

| Motion control | 1-5 ms |

| Sensor feedback loop | <2 ms |

| Emergency stop activation | <50 ms |

Validation for Safety and Compliance

Robots frequently operate close to people, so safety is a top concern. Norms like ISO 10218 and ANSI/RIA R15.06 dictate how industrial robot automation tester should act under fault, collision, or irregular states.

Typical Safety Features to Test:

- Emergency stop operations

- Collide detection sensors

- Speed and separation monitoring

Compliance Checklist:

- Test all stop and slowdown procedures.

- Perform intrusions and verify robot response.

Log all safety events with timestamps for audit.

Tools to Assist:

| Safety Test Area | Tool Example |

| Light curtain detection | SafetyPLC, Safety Relay |

| Force limitation | Force-torque sensors |

| Proximity monitoring | LiDAR, Ultrasonic sensors |

Frequent Firmware and Software Updates

Robotic systems usually receive regular firmware, control logic, or machine learning model updates. These can change the system behavior inadvertently or bring in new bugs.

Challenges Brought by Updates:

- Passed tests may fail now.

- Robot timing or movement profiles change.

- System memory or storage usage may rise unexpectedly.

Testing Guide:

- Keep strict changelogs and versioned test cases.

- Perform a full regression test suite for each update.

- Sandbox and isolate updates for validation prior to production deployment.

Automated Update Testing Process:

- Get update build from engineering team.

- Deploy in staging environment.

- Invoke regression automation (unit + system level).

- Log anomalies and validate fix prior to rollout.

Unclear or Changing Requirements

In actual factory settings, requirements for robotic systems tend to change in the course of implementation. Introduction of new production lines, materials, or processes could change priorities or render earlier assumptions obsolete.

Typical Problems:

- Testing against incomplete specs.

- Features being added mid-sprint.

- Performance criteria change after deployment.

How to Do It:

- Work with stakeholders early and throughout.

- Document modular, reusable test cases.

- Keep a traceability matrix to know which requirements each test verifies.

Sample Traceability Matrix Format:

| Requirement ID | Description | Test Case ID | Status |

| RQ-01 | Robot arm must reset in <2 sec | TC-15 | Passed |

| RQ-02 | Load handling up to 5kg | TC-21 | Failed |

| RQ-03 | Safety halt on proximity <1m | TC-07 | Passed |

Burden of Test Data and Log Analysis

Each test produces logs, sensor data, and state transitions. Over time, this produces big data volumes that must be parsed, interpreted, and leveraged for debugging or enhancement.

Tester Tasks:

- Quickly identify failed tests and root causes.

- Pull trends from multi-gigabyte logs.

- Produce actionable developer and engineer reports.

Efficient Analysis Solutions:

- Parse logs automatically with pattern detection tools.

- Visualize data with tools such as Grafana or Kibana.

Frequently Asked Questions (FAQ)

Q1: What are the necessary skills for an Industrial Robot Automation Tester?

A: PLC programming knowledge, knowledge of embedded systems, robotic simulators familiarity, and basic mechanical/electrical knowledge are essential.

Q2: What are the testing frameworks applicable in this industry?

A: ROS testing tools, Robot Framework (specifically customized for robotics), LabVIEW, and proprietary OEM diagnostic suites.

Q3: In what ways is robotic testing different from standard software QA?

A: Robotic testing includes real-time constraints, hardware interactions, safety validation, and system-level coordination — not only code verification.

Q4: Can test automation be used in industrial robot automation tester?

A: Yes, although with limitations. Test automation is suitable for simulation and regression cases but still needs manual safety validation.

Q5: How do testers approach safety validations in practice?

A: They simulate fault scenarios, employ safety-certified tools, and note responses against compliance standards.

Conclusion

The job of an Industrial Robot Automation Tester is integral to the success of any automated manufacturing line. The more advanced and integrated robots become in core manufacturing processes, the greater the imperative to test them accurately, efficiently, and safely becomes. These testers are no longer simply testing software — they’re working where real-time controls meet mechanical systems, safety standards, and changing production requirements.

From controlling limited access to hardware through firmware updates and digging through massive amounts of test data, every challenge demands quick technical know-how and a systematic strategy. The complexity is not only technical — it’s operational, collaborative, and frequently time-sensitive. But with the right tools, frameworks, and testing methodologies, testers can confidently release robots capable of the demands of industrial life.

The future of production is more and more industrial robot automation tester, and the dependability of that future relies on just how well we test today. The more industries turn toward automation, the more valuable skilled robot automation testers will prove to be.