In recent years, China has emerged as a dominant force in the global robotics market. Factories across the country are increasingly automated, with robots performing tasks that once relied heavily on human labor. This transformation is not just about replacing manpower—it’s about creating a synchronized, efficient, and intelligent industrial ecosystem where machines operate with precision and speed. From automotive assembly lines to electronics production, China robots are driving productivity, reducing operational costs, and improving consistency across industries.

The country’s rapid adoption of robotics is fueled by a combination of technological innovation, domestic manufacturing capabilities, and strategic government initiatives. As the global demand for automation grows, China has positioned itself at the center of this revolution, producing robots that are not only competitive in cost but also advanced in functionality. This leadership extends beyond borders, with Chinese robots being exported and deployed in international manufacturing hubs.

China Robots Dominating the Global Robotics Market

In this guide, we will explain how China has achieved this global dominance, the role of domestic manufacturers, the strategies supporting expansion, and what the future holds for robotics innovation.

Unmatched Growth in Robot Installations

China’s growth in robot installations has been meteoric. Over the past decade, factories across the country have increasingly adopted automation, reducing reliance on manual labor and enhancing productivity. Key sectors driving this adoption include automotive, electronics, and consumer goods. Visit here!

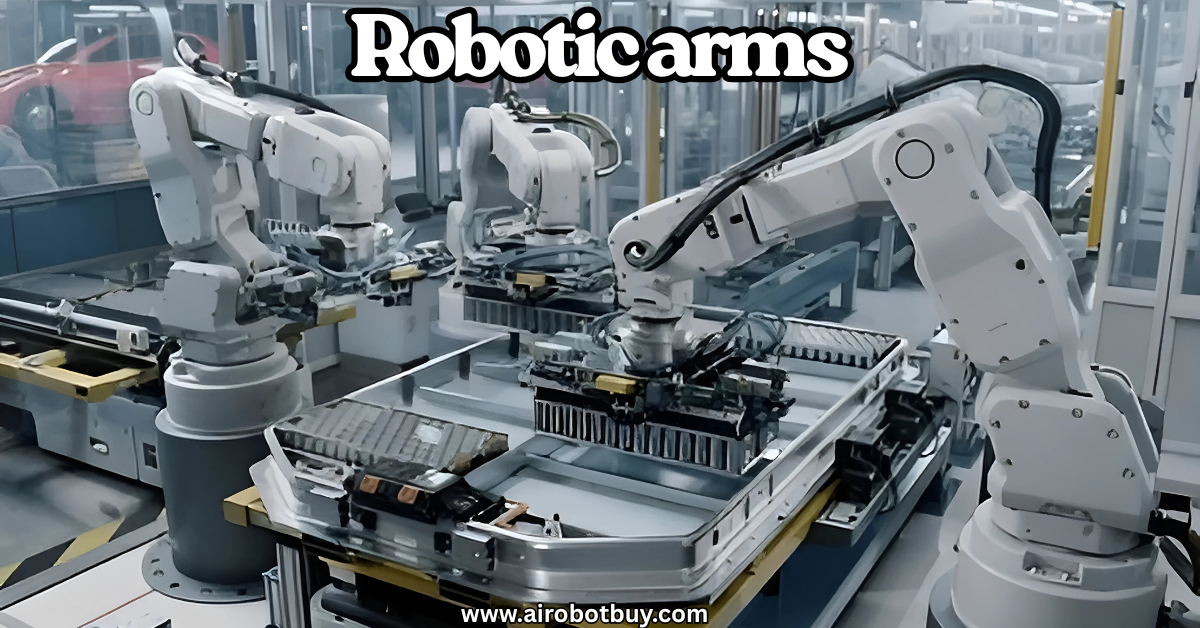

The growth is not just in numbers but in capability. Factories now operate around the clock with synchronized robotics systems, improving throughput and precision. This transformation is cinematic—lines of robots performing tasks in perfect harmony, each movement choreographed for maximum efficiency.

Key Drivers of Growth

- Manufacturing demand: Automotive and electronics industries require high-precision assembly.

- Labor shortages: Automation addresses declining workforce availability.

- Cost efficiency: Robots reduce long-term operational costs.

- Technology accessibility: Domestic production makes robots more affordable.

Installation Statistics Table

| Year | Robots Installed in China | Global Market Share (%) |

|---|---|---|

| 2018 | 140,000 | 36 |

| 2019 | 170,000 | 38 |

| 2020 | 190,000 | 41 |

| 2021 | 220,000 | 44 |

| 2022 | 260,000 | 51 |

| 2024 | 295,000 | 54 |

China robots are now an integral part of industrial operations, driving productivity leaps in both traditional and emerging sectors.

Domestic Manufacturers Leading the Charge

China’s leadership in robotics is underpinned by a strong domestic manufacturing ecosystem. Local companies produce a wide range of robots, from basic assembly arms to advanced AI-powered humanoids. This self-sufficiency reduces reliance on foreign technology and supports rapid scaling.

Domestic manufacturers focus on both quantity and quality, ensuring that robots meet the rigorous demands of high-speed production lines. The cinematic imagery of factories filled with synchronized robotic arms showcases the precision and efficiency of modern Chinese automation.

Factors Behind Domestic Leadership

- Research and Development: Continuous innovation in AI and robotics.

- Cost advantage: Local production lowers prices and increases accessibility.

- Government support: Strategic initiatives boost local manufacturing.

- Industry collaboration: Partnerships between universities, tech hubs, and manufacturers accelerate advancement.

List of Key Robot Types Produced

- Articulated robots: High flexibility for complex tasks.

- SCARA robots: Fast and precise assembly.

- Delta robots: High-speed pick-and-place operations.

- Humanoid robots: Advanced AI-driven machines for testing automation limits.

With domestic production at the core, China robots are designed to meet both national and international demand, ensuring the country maintains an edge in global robotics.

Expanding Global Presence

China’s robotics industry is no longer confined to its borders. Increasingly, Chinese robots are being deployed in factories worldwide, from Southeast Asia to Europe. This global expansion strengthens China’s role as a robotics leader.

Exports are growing rapidly, supported by competitive pricing, advanced features, and strong after-sales support. Chinese robotics companies are adapting to different industrial needs, providing solutions for various production scales. The global movement of robots paints a cinematic picture of China’s technological influence spreading across continents.

Global Reach Highlights

- Exports growth: Industrial robot exports rose 60% in the first half of 2025.

- Strategic regions: Vietnam, Thailand, and other manufacturing hubs are key markets.

- Industry adoption: Automotive, electronics, and consumer goods sectors increasingly rely on Chinese robots.

- Brand recognition: Local brands gain trust through reliability and cost-effectiveness.

Table: China Robot Export Statistics

| Year | Export Value (USD million) | Growth Rate (%) |

|---|---|---|

| 2021 | 410 | 22 |

| 2022 | 520 | 27 |

| 2023 | 580 | 11 |

| 2024 | 670 | 15 |

| 2025 | 746 | 11 |

China robots are thus not only shaping domestic industry but also influencing global production ecosystems.

Government Support and Strategic Initiatives

Government policies have been a critical factor in the rise of Chinese robotics. Programs like “Made in China 2025” and targeted funding initiatives have accelerated research, production, and adoption.

Support comes in multiple forms: financial incentives, infrastructure development, and strategic alliances. These initiatives create an environment where innovation thrives and robotics adoption becomes a national priority. The cinematic vision of robotic innovation centers, testing labs, and smart factories is a testament to this strategic push.

Key Government Measures

- Financial incentives: Grants, subsidies, and tax relief for robotics companies.

- Infrastructure support: Development of high-tech industrial parks.

- Research funding: Universities and labs receive backing for AI and robotics R&D.

- Standards and safety regulations: Ensuring quality and interoperability of robots.

Table: Government Robotics Funding Initiatives

| Initiative | Focus Area | Budget (USD million) | Impact |

|---|---|---|---|

| Made in China 2025 | High-tech manufacturing | 10,000 | Boost domestic robotics production |

| AI+ Robotics Program | AI integration in robotics | 4,500 | Improve intelligence of robots |

| Smart Factory Pilot | Automation adoption | 3,200 | Increase industrial efficiency |

Government strategy has enabled China robots to scale faster and adopt more advanced technologies than many competitors.

The Road Ahead

The trajectory of Chinese robotics suggests continued dominance. Market analysts project a 23% annual growth rate, with the market reaching $108 billion by 2028. Emerging sectors like AI integration, smart logistics, and collaborative robots (cobots) promise to expand applications beyond traditional manufacturing.

China is focusing on the next frontier of automation: fully autonomous factories, intelligent supply chains, and AI-driven production analytics. The cinematic vision of these innovations is a world where robots seamlessly interact with humans and data systems, optimizing every industrial process.

Key Trends for the Future

- AI-powered robotics: Machines capable of self-learning and adaptive operations.

- Cobots: Robots designed to work safely alongside human workers.

- Smart logistics: Automation in warehouses and supply chains.

- Global partnerships: Strategic collaborations to expand presence and technology transfer.

Future Market Projections Table

| Year | Market Size (USD billion) | CAGR (%) |

|---|---|---|

| 2024 | 58 | 22 |

| 2025 | 71 | 23 |

| 2026 | 87 | 23 |

| 2027 | 97 | 23 |

| 2028 | 108 | 23 |

With these trends, China-robots are set to influence the robotics landscape worldwide for years to come.

FAQs About China Robots

Q1: What industries benefit most from China robots?

A: Automotive, electronics, consumer goods, logistics, and e-commerce sectors see the largest gains.

Q2: Are China robots competitive globally?

A: Yes, they offer affordability, reliability, and advanced technology comparable to global competitors.

Q3: How fast is China’s robotics market growing?

A: The market is growing at approximately 23% annually and is projected to reach $108 billion by 2028.

Q4: Does the government support robotics in China?

A: Strongly. Programs like Made in China 2025 provide financial incentives, infrastructure, and R&D funding.

Q5: What types of robots are produced in China?

A: Articulated arms, SCARA robots, delta robots, humanoid robots, and collaborative robots (cobots).

Conclusion

China’s rise in the global robotics market reflects a deliberate and strategic transformation of its industrial landscape. Through massive investments in automation, strong domestic manufacturing, and robust government support, the country has positioned itself as a central player in global robotics. Factories are no longer just production lines—they are dynamic ecosystems where China robots operate with precision, reliability, and efficiency, enhancing productivity and reducing costs.

The combination of technological innovation, competitive manufacturing, and global expansion ensures that Chinese robots are influencing industrial practices beyond the country’s borders. As industries worldwide seek smarter and faster production solutions, the demand for these robots continues to grow. Emerging trends such as AI integration, collaborative robots, and smart logistics indicate that China’s leadership in robotics will remain strong, shaping both the present and future of automation on a global scale.

By understanding the factors behind China’s dominance, businesses, policymakers, and technology enthusiasts can gain insight into the evolving industrial ecosystem. The trajectory of China-robots demonstrates not only technological advancement but also strategic vision, suggesting a future where automation and intelligent systems define the new standards of manufacturing excellence.