The future of industrial automation is no longer confined to static robotic arms and fixed-function machines. As global industries face rising labor shortages, increasing production demands, and the need for greater operational flexibility, a new type of automation is emerging: the Universal Humanoid Robot (UHR). These advanced, human-shaped machines are designed to function in dynamic, human-centric environments—handling diverse tasks such as material transport, machine operation, inspection, and even basic decision-making.

Unlike traditional robots, UHRs bring a new level of intelligence, mobility, and adaptability to the manufacturing floor. With the integration of artificial intelligence, machine learning, and real-time sensory feedback, these robots can quickly learn new processes, collaborate safely with human workers, and operate efficiently in spaces not originally designed for automation.

Leading manufacturers and tech innovators are already deploying UHRs in high-impact settings—from smart factories to complex logistics hubs—demonstrating measurable improvements in productivity and cost-efficiency. As this technology continues to evolve, it offers a powerful solution for industries seeking to modernize without overhauling their entire infrastructure.

In this guide, we will explain what Universal-Humanoid-Robot are, how they work, where they’re being used, and why they represent the next phase of intelligent industrial automation.

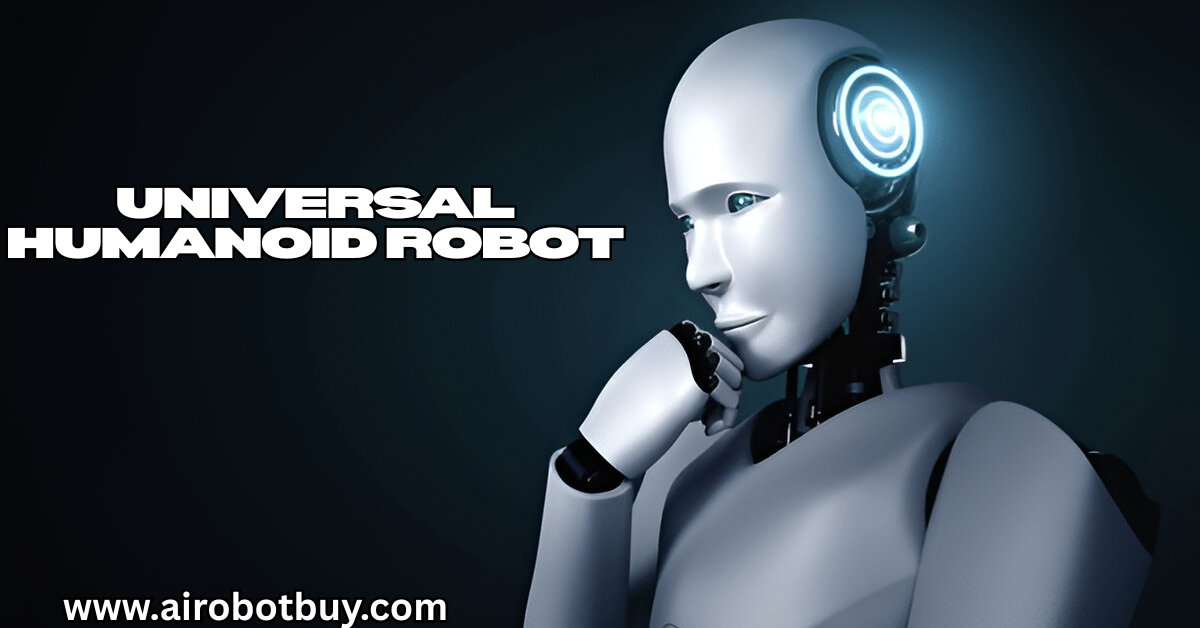

Universal Humanoid Robot Leading the Future of Industrial Automation

The Universal Humanoid Robot (UHR) is redefining the capabilities of automation across industries. Traditional industrial robots, though efficient in repetitive and pre-programmed tasks, are limited by their rigidity and inability to adapt to human-designed environments. In contrast, UHRs are versatile, mobile, and designed to operate alongside humans, performing a wide range of tasks in real time. With advancements in artificial intelligence, machine learning, and robotics engineering, the UHR is quickly becoming a vital asset in modern industrial operations. This article provides a complete, straightforward guide to how UHRs are leading the next era of industrial automation, highlighting their functions, benefits, applications, and future potential. Visit here!

What Is a Universal Humanoid Robot?

A Universal Humanoid Robot is a general-purpose, human-shaped robot capable of executing multiple tasks across various environments. Unlike fixed-function machines, UHRs are designed to work in dynamic, unstructured settings — such as warehouses, production floors, and service areas. These robots typically mimic human anatomy in terms of limbs, joints, and movement, enabling them to navigate stairs, handle tools, interact with touchscreens, and more. UHRs use sensors, cameras, and AI-driven decision-making to perceive and react to their surroundings.

Key Features of a Universal Humanoid Robot

- Human-like Form Factor: Enables operation in environments built for people.

- AI and Machine Learning Integration: Allows task learning, adaptation, and decision-making.

- Mobility and Dexterity: Walks, climbs, lifts, and manipulates objects with precision.

- Multi-functionality: Performs various roles without mechanical reconfiguration.

- Safety Systems: Embedded sensors ensure collision avoidance and safe human interaction.

How UHRs Differ from Traditional Industrial Robots

| Feature | Traditional Robots | Universal Humanoid Robots |

|---|---|---|

| Structure | Fixed or wheeled arms | Bipedal, human-like |

| Task Flexibility | Single-task | Multi-task |

| Adaptability | Low | High |

| Learning Capability | Pre-programmed | AI-powered |

| Environment Compatibility | Structured only | Human environments |

| Cost Efficiency | Long-term, limited use | Broad ROI across use cases |

Benefits of Using Universal Humanoid Robots in Industry

- Flexibility: Can perform various roles such as material handling, inspection, packaging, and more.

- Space Optimization: Navigates existing workspaces without requiring layout changes.

- Cost Savings: Reduces the need for specialized machinery or additional personnel for repetitive tasks.

- Reduced Downtime: Quickly reprogrammed for new tasks without halting operations.

- Worker Support: Assists in physically demanding or repetitive work, reducing injuries.

Core Applications in Industrial Automation

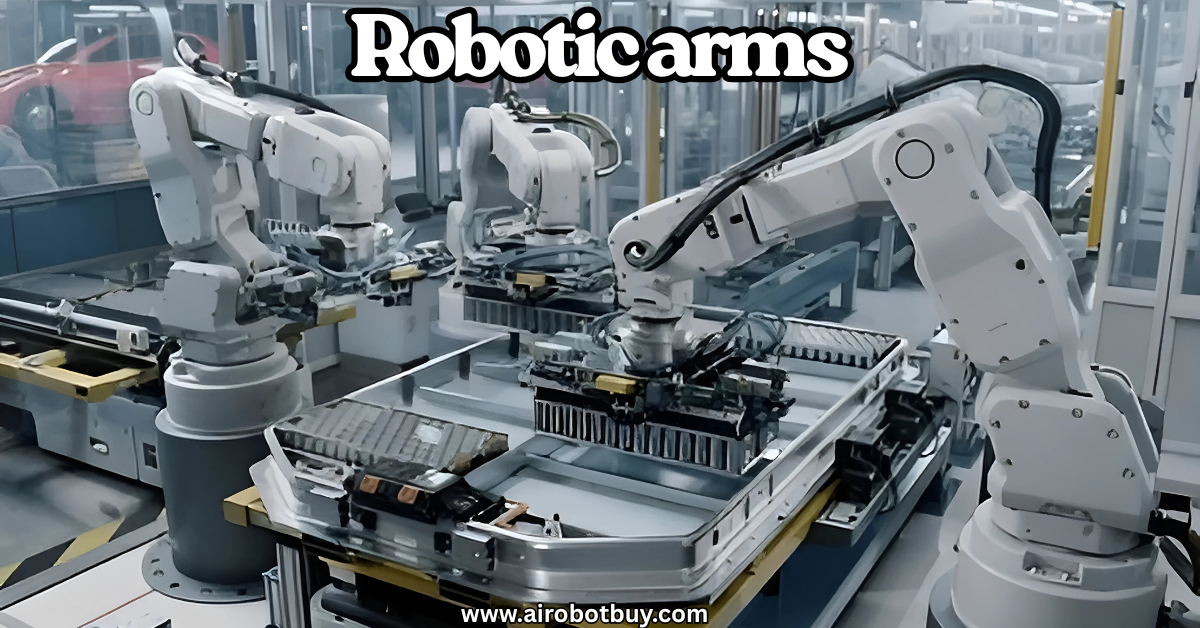

- Manufacturing Lines – Assisting in assembly, part transport, and machine operation.

- Warehousing – Picking, packing, labeling, and transferring goods.

- Logistics – Loading/unloading vehicles, inventory checks.

- Maintenance – Performing diagnostics, basic equipment servicing.

- Quality Control – Using sensors to inspect products visually and structurally.

Technology Behind Universal Humanoid Robots

- Sensors and Cameras: For spatial awareness and object detection.

- Actuators and Motors: Simulate human joint movement.

- Natural Language Processing (NLP): Enables voice commands and communication.

- AI Algorithms: Process data to make decisions and learn from tasks.

- Edge Computing: On-device processing for real-time responsiveness.

Challenges in UHR Deployment

- High Initial Investment: Hardware and integration costs can be significant.

- Battery Limitations: Powering high-mobility robots requires advanced battery management.

- Safety Regulations: Compliance with global and local safety standards is essential.

- Training and Integration Time: Requires alignment with existing systems and staff.

Implementation Strategy for Businesses

- Needs Assessment: Define tasks that a UHR could efficiently support.

- Pilot Testing: Start small with one robot in a limited role.

- Integration Planning: Ensure compatibility with current systems.

- Staff Training: Teach employees how to work with and supervise robots.

- Evaluation: Measure performance, cost savings, and task efficiency.

Q&A Section

Q1: Are UHRs suitable for small to mid-sized enterprises?

Yes. As prices drop and robots become more modular, SMEs can adopt UHRs in targeted roles such as packaging or quality inspection.

Q2: What safety measures are in place for human-robot collaboration?

UHRs come with proximity sensors, collision avoidance systems, and emergency shutoff protocols to ensure safe interaction.

Q3: How long does it take to train a UHR for a new task?

With AI training modules, basic task setup can take a few days to a week depending on complexity.

Q4: Can UHRs work 24/7?

Most robots operate in shifts due to battery limitations, but battery-swapping systems or wired stations allow continuous operation.

Q5: What is the average lifespan of a UHR?

Typically 5–10 years, with regular software updates and hardware maintenance.

Conclusion

The rise of Universal Humanoid Robot marks a significant milestone in the evolution of industrial automation. With their ability to work in human-designed spaces, perform multiple tasks, and learn through artificial intelligence, UHRs are redefining what’s possible on the factory floor and beyond. Unlike traditional automation systems, which are limited by rigidity and high reconfiguration costs, these robots offer flexibility, scalability, and real-time adaptability—all of which are critical for modern industry demands.

Early adopters across manufacturing, logistics, and warehousing are already seeing the benefits: improved operational efficiency, reduced labor costs, and safer working environments. While challenges such as high initial investment and safety regulations remain, rapid advancements in robotics technology and declining costs are paving the way for broader adoption—even among small to mid-sized enterprises.

As industries continue to adapt to digital transformation, Universal Humanoid Robot are not just futuristic concepts—they are practical, high-impact tools ready to meet the complex needs of today’s operations. Businesses that invest early in this transformative technology stand to gain a powerful competitive edge in the years ahead.