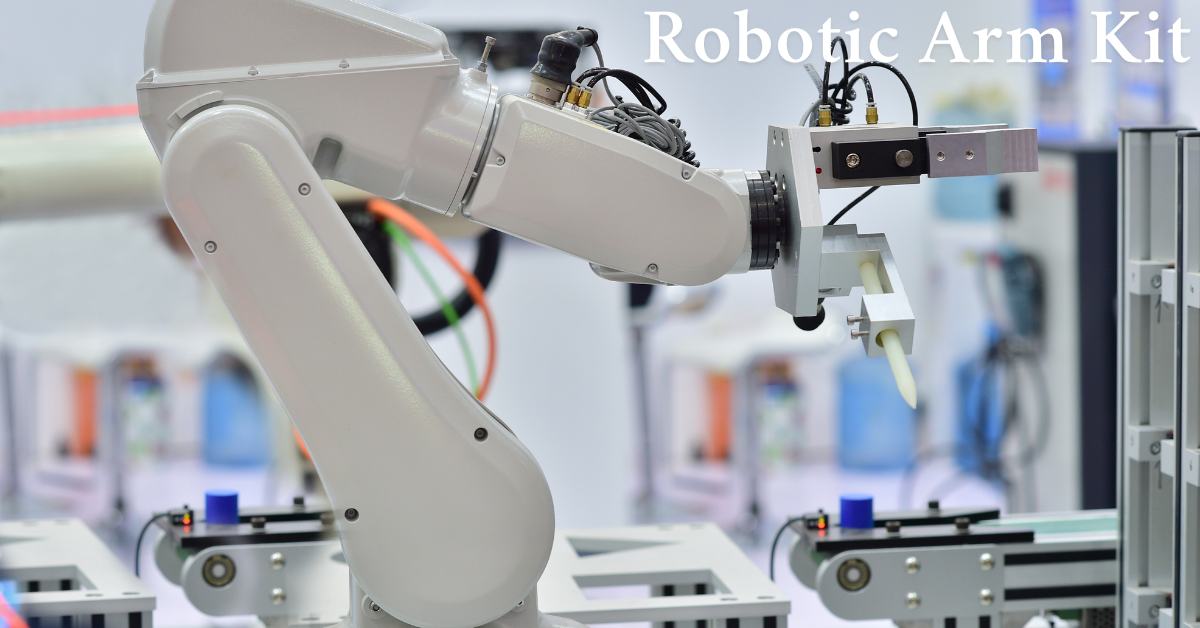

Robotic arms have transformed the manufacturing industry, offering unparalleled precision, efficiency, and automation. These programmable mechanical arms replicate human arm movements to perform complex tasks such as assembly, welding, painting, and material handling. This article explores the types, applications, benefits, and future trends of robotic arms in industrial automation.

What Are Robotic Arms?

A robotic arms is a mechanical device designed to mimic human arm movement. It consists of interconnected joints, actuators, sensors, and end effectors, enabling precise control and movement across multiple axes. Robotic arm are commonly used in factories, laboratories, and even medical fields for high-precision tasks.

Types of Robotic Arm

- Articulated Robotic Arm – Feature multiple rotary joints, providing high flexibility and range of motion.

- Cartesian Robots – Operate on linear axes (X, Y, Z) for precise, controlled movements.

- SCARA Robots – Specialized for horizontal movements, ideal for assembly operations.

- Delta Robots – High-speed parallel robots used in packaging and sorting.

- Collaborative Robots (CoBots) – Designed to work safely alongside humans, enhancing productivity.

Key Features of Robotic Arms

- Multi-Axis Movement – Enables intricate and precise operations.

- End Effectors – Interchangeable tools such as grippers, welding torches, or suction cups.

- Force and Torque Sensors – Ensure controlled movement and prevent damage to objects.

- AI and Machine Learning Integration – Enhances automation and adaptive learning.

- Remote Control and Monitoring – Cloud-based systems enable real-time supervision.

Applications of Robotic Arms

1. Manufacturing and Assembly

- Automated product assembly for electronics, automotive, and consumer goods.

- Precision component fitting in aerospace and heavy machinery.

2. Welding and Painting

- High-accuracy robotic welding in automotive and metal fabrication.

- Consistent spray painting for improved surface coating quality.

3. Material Handling and Packaging

- Lifting and moving heavy materials in warehouses and production lines.

- Sorting and packaging items in food processing and e-commerce.

4. Medical and Pharmaceutical Use

- Assisting in complex surgeries and medical device manufacturing.

- Precise drug handling and packaging in pharmaceutical industries.

5. Research and Development

- Used in laboratories for precise experiments and testing.

- Assisting in robotics research and AI advancements.

Benefits of Robotic Arm

- Improved Efficiency – Robots work faster and continuously without fatigue.

- Enhanced Accuracy – Reduces human errors and maintains consistency.

- Cost Savings – Lowers long-term labor and operational costs.

- Increased Safety – Minimizes workplace hazards in high-risk environments.

- Scalability – Easily reprogrammed and adapted to new tasks.

Challenges and Limitations

- High Initial Cost – Investment in robotic arm can be expensive.

- Complex Programming – Requires skilled engineers for setup and maintenance.

- Workforce Displacement – Automation may reduce human jobs in certain sectors.

- Integration Issues – Compatibility with existing production lines can be challenging.

Future of Robotic Arms

- AI-Powered Automation – Smarter robots capable of adaptive learning.

- Lightweight and Flexible Designs – Enhancing mobility and usability.

- 5G and IoT Connectivity – Enabling real-time data exchange and monitoring.

- Human-Robot Collaboration – Improving safety and efficiency in shared workspaces.

- Sustainable Robotics – Developing energy-efficient and eco-friendly robotic solutions.

Conclusion

Robotic arms are at the forefront of precision manufacturing, enhancing productivity, accuracy, and automation. As technology advances, their capabilities will expand further, revolutionizing industries worldwide.

Stay tuned for our next article on Industrial Robotics and Their Impact on Smart Factories!