In an era where speed, precision, and efficiency define competitiveness, industrial robotics has emerged as the backbone of modern manufacturing. From automotive giants like Tesla to small-scale precision engineering workshops, businesses worldwide are leveraging robots to streamline operations, reduce errors, and stay ahead in the race. At ChinaRobots.com, we’re at the forefront of this revolution, delivering cutting-edge robotic solutions that redefine what’s possible on the factory floor.

This blog dives deep into the world of industrial robotics, exploring its current trends, undeniable benefits, and the exciting future it promises. Whether you’re a plant manager looking to upgrade your assembly line or a decision-maker curious about automation, this guide will equip you with actionable insights.

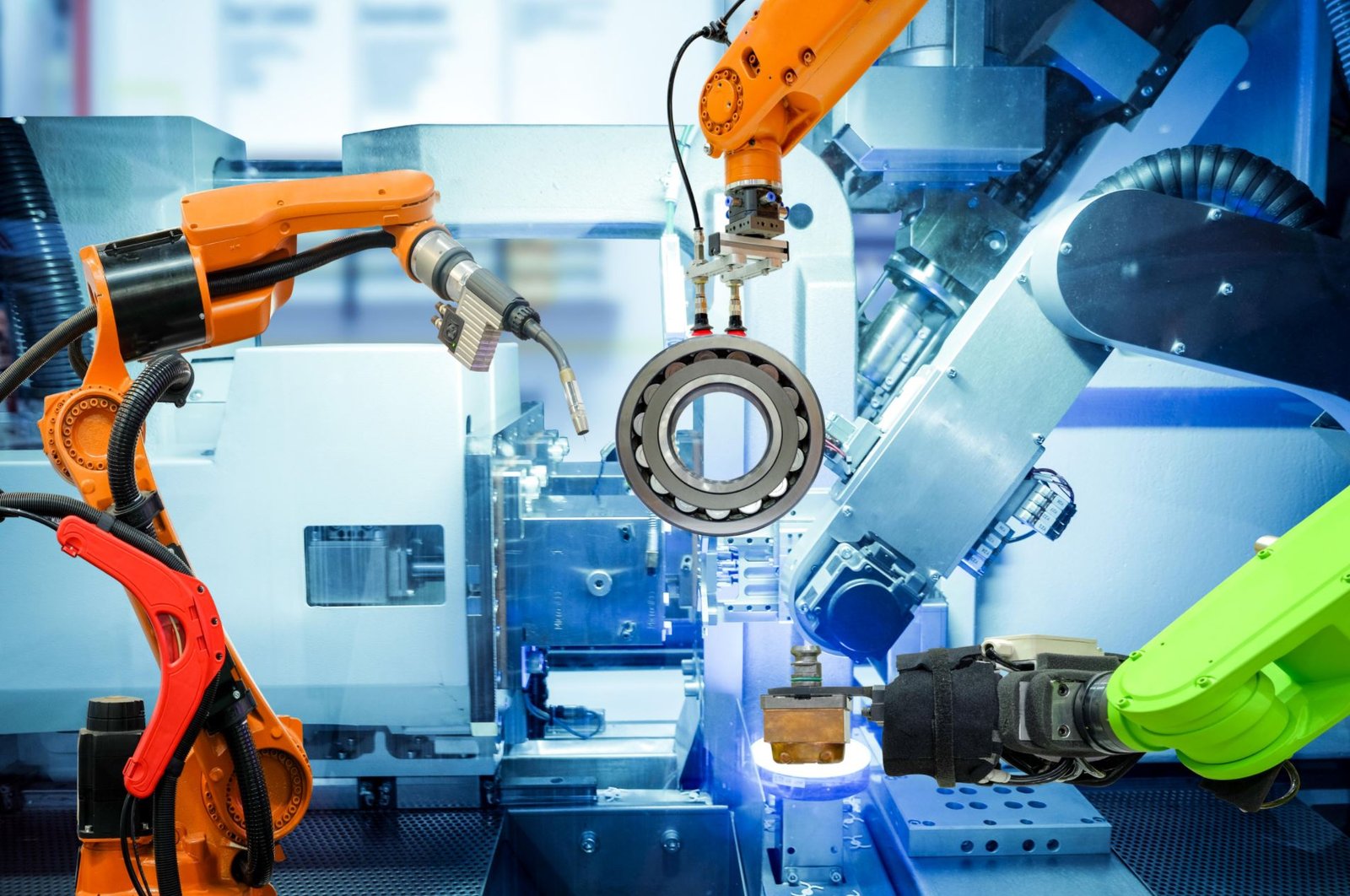

Current Trends in Industrial Robotics

1. Collaborative Robots (Cobots)

Gone are the days when robots were confined to safety cages. Collaborative robots, or cobots, are designed to work alongside humans, combining the precision of machines with the problem-solving skills of workers. For example, our Model C3 Cobot at ChinaRobots.com assists in tasks like screwdriving and quality inspection, reducing repetitive strain injuries by 60% in partner factories.

Cobots are particularly popular in industries requiring flexibility, such as electronics assembly and food packaging. With features like force-limiting sensors and intuitive programming interfaces, cobots are making automation accessible to small and medium-sized enterprises (SMEs).

2. AI-Driven Predictive Maintenance

Unplanned downtime costs manufacturers $50 billion annually. Modern industrial robotics now integrate AI-powered sensors that predict equipment failures before they occur. For instance, our SmartFactory Suite analyzes vibration, temperature, and performance data to alert technicians about motor wear or calibration issues, slashing downtime by up to 30%.

Predictive maintenance not only saves costs but also extends the lifespan of robotic systems. By addressing issues proactively, businesses can avoid costly breakdowns and maintain consistent production schedules.

3. IoT and Smart Factory Integration

Industry 4.0 is here, and it’s all about connectivity. Industrial robotics are now nodes in a vast IoT ecosystem, sharing real-time data with ERP systems, AGVs, and cloud platforms. At ChinaRobots.com, our robots support protocols like OPC UA and MQTT, enabling seamless communication across legacy and modern systems.

Smart factories leverage this connectivity to optimize workflows, monitor energy consumption, and even automate decision-making. For example, a robotic arm in a smart factory can adjust its speed based on real-time demand data, ensuring maximum efficiency.

Key Benefits of Industrial Robots

1. Increased Productivity and Precision

Industrial robotics operate 24/7 without fatigue, delivering consistent output with micron-level precision. For example, our Model X500 Robotic Arm achieves repeatability of ±0.02mm, making it ideal for high-precision tasks like welding and PCB assembly.

2. Cost Reduction Through Automation

While the initial investment in robotics can be significant, the long-term ROI is undeniable. Robots reduce labor costs, minimize material waste, and optimize energy usage. A case study from one of our clients showed a 40% reduction in operational costs within two years of deploying our robotic systems.

3. Enhanced Workplace Safety

Robots handle hazardous tasks like heavy lifting, chemical handling, and high-temperature operations, reducing workplace injuries. Our SafetyGuard System ensures compliance with ISO safety standards, providing peace of mind for plant managers.

Challenges and Solutions

1. High Upfront Costs

The initial investment in robotics can be a barrier for SMEs. However, ChinaRobots.com offers flexible financing options and ROI-based consultations to help businesses make informed decisions.

2. Workforce Training

Integrating robots requires skilled operators. We provide on-site training programs and user-friendly interfaces to bridge the skills gap.

3. Integration with Legacy Systems

Our robots are designed for compatibility with existing systems, minimizing disruption during deployment.

Future Trends to Watch

1. Autonomous Mobile Robots (AMRs)

AMRs are revolutionizing material handling in warehouses and factories. Equipped with advanced navigation systems, these robots can transport goods autonomously, reducing reliance on human labor.

2. Digital Twins for Simulation

Digital twins allow manufacturers to simulate and optimize robotic workflows before deployment. This technology reduces setup time and ensures optimal performance.

3. Sustainability in Robotics

As industries prioritize sustainability, robots are being designed for energy efficiency and recyclability. Our EcoBot Series consumes 20% less energy than traditional models, aligning with green manufacturing goals.

Case Study: Boosting Efficiency with ChinaRobots.com

A leading automotive parts manufacturer partnered with ChinaRobots.com to automate their assembly line. By deploying our Model X500 Robotic Arms and SmartFactory Suite, they achieved:

- 40% increase in production output

- 30% reduction in downtime

- 20% lower energy consumption

Conclusion

Industrial robotics is no longer a luxury—it’s a necessity for businesses aiming to thrive in a competitive landscape. At ChinaRobots.com, we’re committed to delivering innovative, reliable, and cost-effective robotic solutions that empower your business.

Ready to transform your manufacturing process? Explore our range of industrial robotics or contact our experts today to schedule a demo.